ABOUT

Analysis of the Outstanding Performance of Copper-Molybdenum-Copper (CMC) Electronic Packaging and Heat Sink Materials

Electronic Packaging and Heat Sink Materials

Material Introduction

Electronic packaging involves placing a functional integrated circuit chip (including semiconductor integrated circuit chips, thin-film integrated circuit substrates, and hybrid integrated circuit chips) within a suitable housing. This provides the chip with a stable and reliable operating environment, protecting it from or minimizing external environmental influences, and ensuring stable and normal function. The packaging also serves as a means of connecting the chip’s input and output terminals to the outside, forming a complete integrated circuit with the chip. Electronic packaging materials are required to possess certain mechanical strength, good electrical properties, heat dissipation performance, and chemical stability. Different packaging structures and materials are selected depending on the type of integrated circuit and its intended use.

Heat dissipation is an inevitable byproduct of power electronic devices and circuits. Heat sink materials help dissipate heat from the chip and transfer it to the surrounding air.

Molybdenum-copper, tungsten-copper, CMC, and CMCC materials combine the low thermal expansion of molybdenum and tungsten with the high thermal conductivity of copper. They effectively dissipate heat from electronic devices, facilitating cooling of various products such as IGBT modules, RF power amplifiers, and LED chips. They can be used as insulating metal substrates, thermal control plates, heat sinks, and lead frames in large-scale integrated circuits and high-power microwave devices.

Power Semiconductor Packages

IGBT Modules

Product Specifications

We offer the following products for power electronic devices and circuits:

Heat Sink Materials

– CMC, CMCC

– Molybdenum Element

Electronic Packaging Materials

– AlSiC

– AlSi

Tungsten-Copper Alloy

Product Advantages: The product has extremely low porosity, with a specific surface area measured by the BET method half that of domestic competitors (compared using 100 5*5*52mm samples). The product also exhibits excellent airtightness, passing a helium mass spectrometer leak test with a value of <5*10-9 Pa·m³/s. No activated sintering elements such as iron, nickel, cobalt, or manganese are added. This product offers excellent thermal conductivity and thermal expansion matching. It also boasts excellent machining accuracy, surface finish, and flatness. Electroplating is also available.

Product Specifications: Bare tungsten copper die with nickel or gold plating.

Molybdenum-copper alloy

Product Advantages: Compared to tungsten copper alloys, molybdenum-copper alloys have a lower density. The product boasts extremely low porosity, with a surface area measured by the BET method half that of domestic counterparts (compared using 100 5*5*52mm samples). This product exhibits excellent airtightness and can fully pass a helium mass spectrometer leak test with a value of <5*10-9 Pa·m³/s. It also boasts high thermal conductivity and a low coefficient of thermal expansion, as well as excellent machining accuracy, surface finish, and flatness. Electroplating is also available.

Product Specifications: Bare molybdenum copper die with nickel or gold plating.

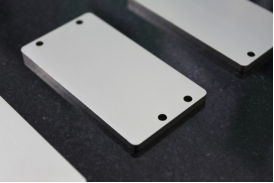

Copper-Molybdenum-Copper-Copper, Copper-Molybdenum-Copper

Product Advantages: CMCC (Copper-Molybdenum-Copper-Copper) and CMC (Copper-Molybdenum-Copper) are three-layer materials with a core of molybdenum-copper or molybdenum, coated on both sides with copper. With a lower coefficient of thermal expansion and thermal conductivity far superior to WCu and MoCu, they offer an optimal alternative for high-power electronic components, helping to cool various high-power components such as IGBT modules.

Product Specifications: We can provide customers with laminated materials in various thicknesses and with varying numbers of layers to meet their diverse application requirements.

Typical Heat Sink Material Performance Table

Molybdenum Sheet

Product Advantages: Our molybdenum sheet offers excellent thermal and electrical conductivity, and its coefficient of thermal expansion is highly compatible with the substrate. We offer both bare die and plated products. These products are widely used in power semiconductor devices, including high-power thyristors and fast-acting thyristors.

Product Specifications: Round molybdenum wafer: Thickness: 0.05-7.0 mm; Diameter: 2.5-150.0 mm

AlSiC

Product Advantages: (AlSiC) aluminum silicon carbide IGBT substrates are essential components for high-speed rail systems. Aluminum silicon carbide composites are a new material that combines silicon carbide ceramic with aluminum metal. They combine the advantages of both ceramic and metal, offering high thermal conductivity, low thermal expansion coefficient, good specific stiffness, and lightweight properties. They are ideal substrates and backing materials for power electronics, ensuring excellent performance when soldered to electronic chips. IGBTs packaged on AlSiC substrates are widely used in industries such as high-speed rail drives, subway drives, new energy vehicles, wind power generation, and welding robots.

AlSiC

Product Advantages: Primarily used in electronic packaging, AlSiC is used as the base, housing, case, and cover of electronic power devices such as microwave power devices, integrated power modules, and T/R modules. The AlSiC alloy provides excellent compatibility, improved heat dissipation, and significantly extends the service life and reliability of packaged high-power modules. The material has the characteristics of light weight (density 2.4-2.7g/cm3), high thermal conductivity, low thermal expansion coefficient, high rigidity, easy machining, good surface plating and welding properties, good material density, high temperature resistance and corrosion resistance.

Keyword:

Heat Sink

We Exist to Make Your Projects Successful

Fill out the form below and someone from our team will be in touch with you!

FOTMA Delivers Professional Ultra-Dense Solutions, Lighter on Cost, Heavier on Performance.

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074