BLOGS

Understanding Titanium Alloy Prices: Factors, Trends, and Sourcing

Procuring titanium alloys requires a deep understanding of their complex pricing structure. As an after-sales engineer, I frequently observe how fluctuating costs impact project budgets and material selection. Gaining insight into the factors driving these prices enables informed decision-making, ensuring both cost-effectiveness and optimal material performance for critical applications. Why Understanding Titanium Alloy Pricing is Crucial for Industrial Procurement 1. The strategic importance of titanium in advanced industries Titanium alloys are indispensable in advanced industries due to their exceptional strength-to-weight ratio, outstanding corrosion resistance, and biocompatibility. Aerospace, medical, chemical processing, and marine sectors rely heavily on these properties for critical components. For instance, in aerospace, titanium’s lightweight nature directly translates to fuel efficiency and increased payload capacity, making it a strategic material despite its higher cost. Similarly, in medical implants, its biocompatibility and resistance to bodily fluids are non-negotiable. The performance advantages offered by Titanium Alloy (Ti-Alloy) often outweigh the initial acquisition cost, especially when considering the total lifecycle cost of a component. 2. The economic impact of material costs on project viability The cost of raw materials significantly impacts project budgets and overall economic viability. For projects utilizing titanium alloys, material costs can represent a substantial portion of the total expenditure. Unexpected price fluctuations can disrupt financial planning and lead to budget overruns. Therefore, a thorough understanding of titanium alloy pricing allows procurement managers and engineers to accurately forecast costs, negotiate better deals, and select appropriate materials that balance performance requirements with financial constraints. This strategic approach ensures project success and maintains profitability. Key Factors That Significantly Influence Titanium Alloy Prices 1. How raw material availability and extraction costs affect pricing The price of titanium alloy is fundamentally linked to the availability and extraction costs of its primary raw material: titanium ore, primarily ilmenite and rutile. These ores are not uniformly distributed globally, leading to concentrated mining operations in specific regions. The extraction process itself is energy-intensive and complex, involving several stages of chemical processing to produce titanium sponge, the precursor to titanium metal. Any disruptions in mining operations, geopolitical instability in producing regions, or increases in energy prices directly translate to higher production costs for titanium sponge, subsequently impacting the final price of Titanium Alloy (Ti-Alloy). 2. The role of manufacturing processes and technological advancements in cost determination Manufacturing titanium alloys involves sophisticated and energy-intensive processes, including melting, forging, rolling, and machining. These processes require specialized equipment and

Unveiling Porous Titanium Sheets: Properties, Applications, and Supplier Insights

Porous titanium sheets offer exceptional properties for demanding industrial applications. Understanding their unique characteristics and diverse uses is crucial for engineers and procurement professionals. This article provides a comprehensive overview, highlighting key features and guiding you through supplier selection, with insights from Hubei Fotma Machinery Co., Ltd. Understanding the Unique Characteristics of Porous Titanium Sheets Porous titanium is a material engineered with an interconnected network of pores, distinguishing it from solid titanium. This intricate structure imparts a unique combination of properties, making it highly valuable across various advanced industries. The controlled porosity significantly influences the material’s performance, offering advantages in specific applications where traditional solid metals fall short. What Defines Porous Titanium Material? Porous titanium material is characterized by its internal void spaces, or pores, which are deliberately created during its manufacturing process. These pores can be uniformly distributed or gradient, and their size typically ranges from nanometers to several hundred micrometers. The primary goal of introducing porosity is to enhance specific material functions, such as filtration efficiency, biocompatibility, and reduced weight, without compromising the inherent strength and corrosion resistance of titanium. The material’s architecture is critical, as the size, distribution, and interconnectivity of these pores directly impact its overall performance. Key Physical and Chemical Properties Porous titanium sheets retain many of the excellent properties of solid titanium while gaining new functionalities due to their porous nature. Manufacturing Processes for Sintered Titanium Sheets The production of porous titanium sheets involves specialized techniques to create and control the desired pore structure. Sintering is a prevalent method, where titanium powder particles are heated to a temperature below their melting point, causing them to bond together and form a solid, porous mass. Common manufacturing processes include: These processes enable the production of porous titanium sheets with tailored properties to meet specific application requirements. Diverse Applications of Porous Titanium Across Industries The unique combination of properties in porous titanium sheets, including biocompatibility, corrosion resistance, and controlled porosity, makes them indispensable in a wide array of advanced industrial sectors. We consistently see new applications emerging as research and development progress. Porous Titanium in Biomedical Implants and Devices The medical field is a primary beneficiary of porous titanium technology. Its excellent biocompatibility and the ability to promote bone ingrowth are critical for long-term success in various implantable devices. Filtration and Separation Technologies Using Titanium Foam The precise and controllable pore structure of titanium foam makes it

All You Need to Know About Copper Nickel Alloy Suppliers

In today’s industrial landscape, copper nickel alloys have become indispensable materials across multiple sectors, from marine engineering to petrochemical applications. Finding reliable copper nickel alloy suppliers who can deliver quality materials consistently is crucial for project success. This comprehensive guide will help you navigate the supplier selection process and make informed purchasing decisions. Need high-quality copper nickel alloys for your project? Contact our expert team today for customized solutions and competitive quotes. The Basics of Copper Nickel Alloys Copper nickel alloys, also known as cupronickel or Cu-Ni alloys, are versatile materials composed primarily of copper with nickel content ranging from 2% to 30%. The most common grades are 90/10 (90% copper, 10% nickel) and 70/30 (70% copper, 30% nickel), each offering distinct properties suited for specific applications. These alloys possess exceptional corrosion resistance, particularly in marine environments, making them ideal for seawater applications. Their inherent antimicrobial properties, excellent thermal conductivity, and remarkable resistance to biofouling have established them as the material of choice for critical infrastructure projects worldwide. Key Factors When Selecting Copper Nickel Manufacturers Quality Certifications and Standards When evaluating copper nickel suppliers, certifications are non-negotiable. Reputable manufacturers should hold ISO 9001:2015 certification at minimum, with many also maintaining ASME, ASTM, and industry-specific approvals. These certifications ensure that the cupronickel manufacturers follow stringent quality control processes throughout production. Leading suppliers typically comply with international standards including ASTM B466, ASTM B467, and ASTM B111 for tubes, while sheet materials follow ASTM B122 specifications. Always request material test certificates (MTCs) and third-party inspection reports to verify composition and mechanical properties. Product Range and Inventory Capabilities Top-tier copper nickel alloy suppliers maintain comprehensive product portfolios including: A supplier’s inventory depth directly impacts project timelines. Cu-Ni alloy distributors with substantial stock can accommodate urgent requirements, while those with limited inventory may cause costly delays. Ask about typical lead times for standard versus custom orders. Technical Support and Customization Services from Copper Nickel Alloy Suppliers Exceptional copper nickel pipe manufacturers don’t just supply materials—they provide value-added engineering support. This includes material selection guidance, application-specific recommendations, and custom fabrication capabilities. Whether you need specialized dimensions, unique alloy compositions, or specific surface finishes, suppliers with in-house technical teams can optimize solutions for your exact requirements. Unsure which copper nickel grade suits your application? Our materials engineers offer free consultations to help you choose the optimal solution. Types of Copper Nickel Alloy Suppliers Primary Producers and Mills These are integrated cupronickel manufacturers operating smelting and rolling facilities. They produce raw materials from refined

How to Find Reliable Chinese Titanium Pipe Distributors?

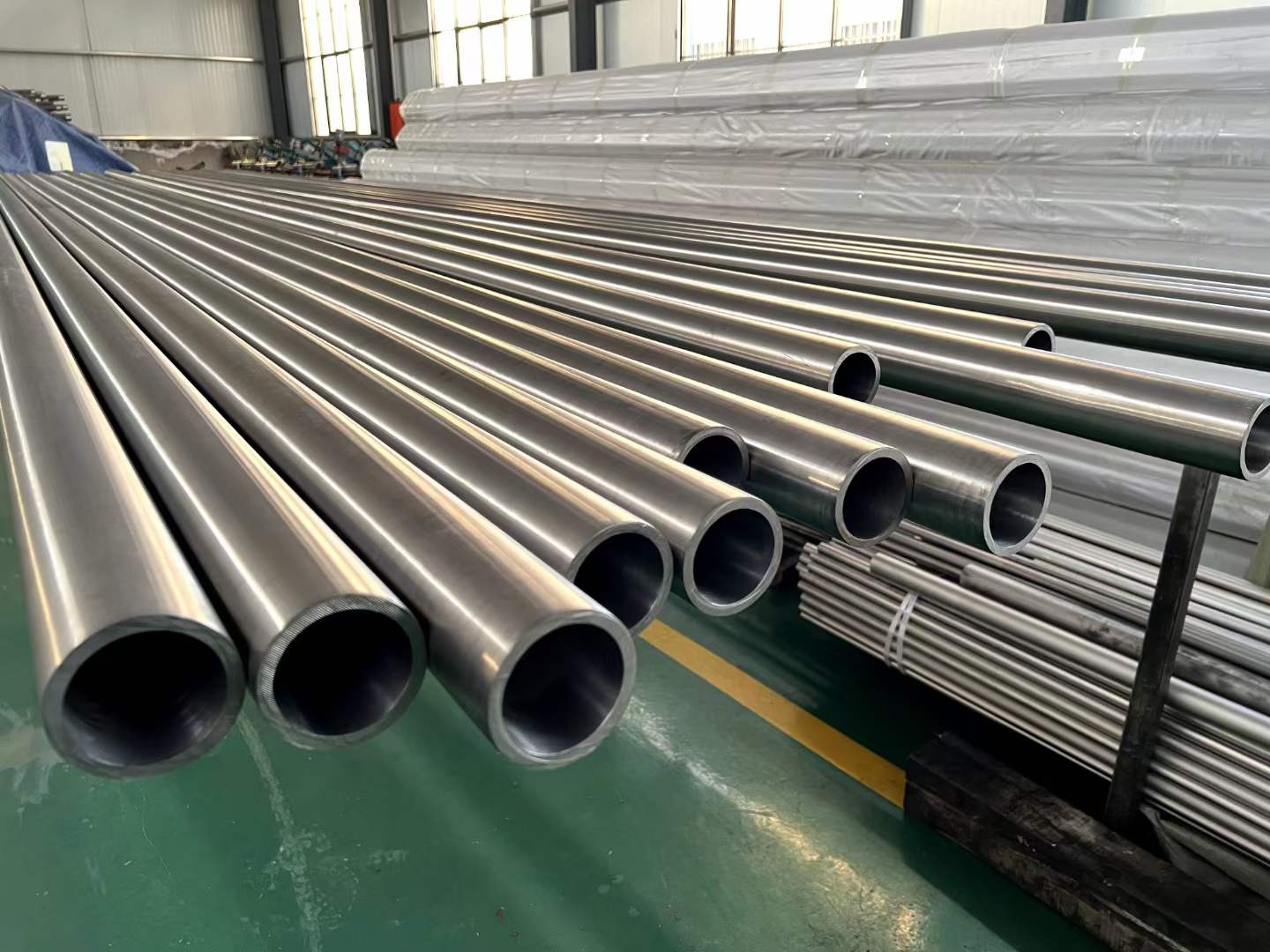

The global demand for titanium tubing has surged dramatically over the past decade, driven by expanding applications in aerospace, medical devices, chemical processing, and marine engineering. As industries worldwide seek cost-effective solutions without compromising quality, many procurement managers are turning their attention to titanium tube manufacturers in China. This comprehensive guide explores the landscape of Chinese titanium alloy tube providers and offers insights into navigating this complex market. Understanding the Chinese Titanium Tube Suppliers Market China has emerged as a dominant force in titanium production and processing, accounting for a significant portion of global titanium supply. The country’s titanium tube manufacturing sector has evolved from primarily serving domestic markets to becoming a major player in international trade. Today, titanium pipe suppliers from China offer products that meet international standards including ASTM, ASME, and DIN specifications. Types of Titanium Alloy Tubes and Products Available from Chinese Manufacturers Chinese titanium alloy tube providers typically offer an extensive range of products to meet diverse industry requirements. Seamless titanium tubes are manufactured using advanced extrusion and cold rolling techniques, producing tubes with superior mechanical properties and surface finish. Welded titanium pipes, created through TIG or laser welding processes, offer cost advantages for applications where seamless construction isn’t mandatory. The material grades available from titanium tubing wholesalers from China span from commercially pure titanium (Grade 1, 2, 3, and 4) to various titanium alloys. Grade 2 remains the most popular choice due to its excellent balance of strength, corrosion resistance, and formability. For more demanding applications, titanium extrusion suppliers can provide specialty alloys like Ti-6Al-4V (Grade 5), which offers superior strength-to-weight ratios ideal for aerospace components. Key Advantages of Sourcing from China Metal Tube Suppliers Cost competitiveness represents perhaps the most compelling reason companies engage with China metal tube suppliers. Lower labor costs, government support for manufacturing industries, and economies of scale enable Chinese manufacturers to offer pricing that’s typically 20-40% lower than Western counterparts. However, cost shouldn’t be the sole determining factor in supplier selection. Production capacity is another significant advantage. Many metal tubing suppliers in China operate large-scale facilities capable of handling substantial orders with relatively short lead times. This scalability proves invaluable for projects requiring large quantities or businesses experiencing rapid growth. Technological advancement in Chinese titanium tube manufacturing has accelerated impressively. Leading facilities now employ state-of-the-art equipment comparable to operations anywhere globally. Automated production lines, precision testing instruments, and quality management

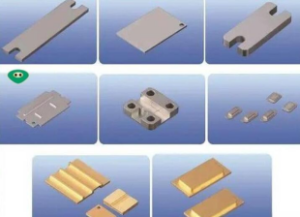

A North American Electronics Engineer’s Successful Purchase of Molybdenum Copper Alloy (MoCu) Heat Sinks on TUNGSTENBUY

In the fall of 2023, Dr. Elena Carter, a senior electronics engineer at a cutting-edge semiconductor company in Canada, was racing to solve a critical thermal management issue. Her team was developing a high-power radar module for aerospace applications—one that generated extreme heat during operation while requiring strict weight control. Traditional aluminum heat sinks lacked sufficient thermal conductivity, and tungsten-copper (WCu) options were too dense, adding unwanted weight to the module. After researching advanced thermal materials, Dr. Carter realized molybdenum copper alloy (MoCu) was the ideal solution: it offered high thermal conductivity while being 30% lighter than WCu. However, local U.S. suppliers either couldn’t meet the module’s ultra-tight flatness tolerance (±0.02mm) or quoted lead times of 16 weeks—far beyond her project’s 8-week deadline. A targeted search for “precision MoCu heat sinks” led her to WWW.TUNGSTENBUY.COM’s dedicated product page for Molybdenum Copper Alloy (MoCu) Heat Sinks. What immediately caught Dr. Carter’s attention was the page’s detailed breakdown of FOTMA MoCu’s advantages. The emphasis on military-grade quality (100% X-ray inspection + helium leak testing, compliance with GJB548B and MIL-STD-883 standards) aligned perfectly with her aerospace project’s requirements. She also noted the full customization capabilities—adjustable Mo/Cu ratios (50/50 to 85/15), precision etching, and microchannel machining—which meant the heat sinks could be tailored to her module’s exact needs. Most compelling was the value proposition: performance rivaling top brands like Plansee and H.C. Starck at 60–70% of the cost. Dr. Carter filled out the “Custom Inquiry” form, attaching a 2D drawing of the heat sink (40mm x 30mm x 5mm, with four 2mm-diameter mounting holes, a Mo70Cu30 ratio request, and a flatness requirement of ±0.01mm) and a note about her urgent timeline. To her surprise, a response landed in her inbox just 6 hours later—sent by Ms. Cherry, a technical sales representative specializing in MoCu components. Cherry didn’t just confirm feasibility; she provided a deep engineering assessment: she verified that the ±0.01mm flatness could be achieved with precision grinding, recommended a nickel-plated surface (to enhance corrosion resistance for the module’s enclosed environment), and highlighted that FOTMA’s MoCu’s low CTE (6.0–8.5×10⁻⁶/°C) would match the GaN chips in the radar module, reducing thermal stress by 70%. She also offered to produce 5 prototype units first for thermal testing, with a quote breaking down costs for raw MoCu material, CNC machining, grinding, nickel plating, and expedited FedEx shipping (guaranteed 5-day delivery to Toronto). Crucially, Cherry outlined a production timeline that fit Dr.

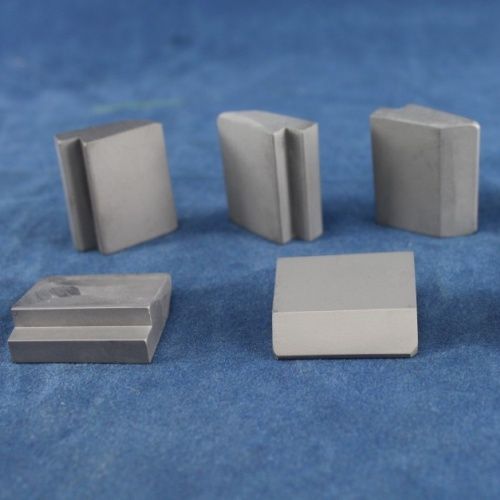

A European Auto Enthusiast’s Smooth Purchase of Tungsten Alloy Weights on TUNGSTENBUY

In the summer of 2024, Marco Rossi, the owner of a high-end car modification workshop in Milan, Italy, encountered a unique challenge. A regular client had commissioned him to optimize the weight distribution of a vintage sports car—specifically, to add precision-balanced weights to the chassis without compromising the vehicle’s original aesthetics. Marco knew that tungsten alloy was the ideal material for this task: it offers exceptional density (far higher than steel or lead, meaning smaller, more discreet weights) and corrosion resistance, which is crucial for preserving the car’s value. However, local suppliers in Italy only offered standard-sized tungsten weights, which couldn’t fit the custom mounting points on the vintage chassis. After scouring European industrial supply platforms with no luck, Marco stumbled upon WWW.TUNGSTENBUY.COM while researching “custom tungsten alloy components.” What caught Marco’s attention first was the website’s dedicated “Tungsten Alloy Weights” category, which included subsections for automotive, aerospace, and marine applications. Unlike generic suppliers, TUNGSTENBUY explicitly highlighted its custom manufacturing capabilities—a detail Marco called “a game-changer.” He found a technical specification page explaining that the company could produce tungsten alloy weights in any shape (from small cylinders to complex geometric designs) with a density range of 18.0-18.5 g/cm³, and even offered surface treatments like black oxide coating to match the car’s undercarriage. To confirm feasibility, Marco uploaded a 3D CAD file of his custom weight design (a 25mm x 15mm x 8mm rectangular block with two M5 threaded holes) via the website’s “Custom Quote” form, along with a note about the required density (18.3 g/cm³) and a deadline of 4 weeks (the client’s car show was fast approaching). To Marco’s delight, he received a response from a technical sales specialist named Alex within 8 hours—impressive, considering the 7-hour time difference between Milan and TUNGSTENBUY’s headquarters. Alex’s email included a detailed engineering review of the CAD file: he confirmed that the design was manufacturable, suggested a minor adjustment to the thread depth to improve durability, and provided a quote for 12 units (the number Marco needed for full chassis balancing). The quote was transparent, breaking down costs for raw materials, CNC machining, surface coating, and DHL express shipping to Milan—with no hidden surcharges. Alex also offered to produce a single prototype first, so Marco could test fit and weight before approving the full order. Marco agreed to the prototype plan, and Alex sent a payment link for the prototype (50% of

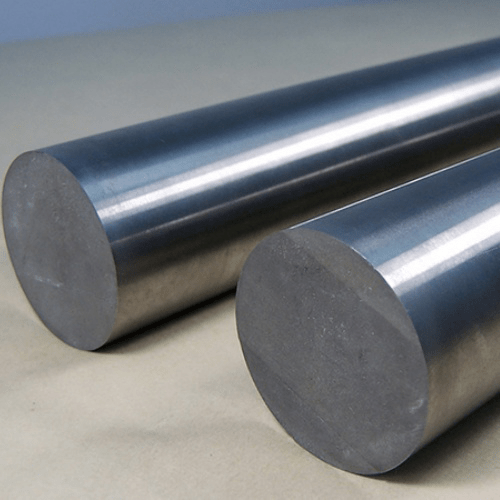

Thomas Mitchell ‘s Successful Shopping Experience

In early 2024, Mr. Thomas Mitchell, a procurement manager at a leading aerospace components manufacturer based in Seattle, USA, faced an urgent challenge. His team needed high-purity tungsten rods—with a minimum purity of 99.95% and specific dimensional tolerances—to meet a critical production deadline for a new aircraft engine project. After weeks of searching through local suppliers who either couldn’t meet the purity requirements or had lead times exceeding 12 weeks, Mr. Mitchell turned to international sourcing, where he discovered WWW.TUNGSTENBUY.COM. What initially drew Mr. Mitchell to the website was its detailed product categorization. Unlike other platforms that buried technical specifications, TUNGSTENBUY clearly listed tungsten rods under its “Industrial Tungsten Products” section, with downloadable PDF certificates of analysis (CoA) for each grade. He quickly identified a 99.95% purity tungsten rod option that matched his dimensional needs (15mm diameter, 300mm length) but had questions about custom cutting and batch consistency. He submitted an inquiry via the website’s live chat feature at 3:00 PM Seattle time—expecting a response the next day due to time zone differences. To his surprise, a customer service representative named Lisa replied within 15 minutes, providing detailed answers about the custom cutting process and offering to share a sample CoA from the latest production batch. Impressed by the responsiveness, Mr. Mitchell requested a formal quote for 500 units, along with a request for a small sample to verify quality before full production. Lisa processed the quote within 24 hours, including transparent pricing (no hidden fees), a 7-day production timeline for the sample, and a 4-week lead time for the full order—well within his project’s deadline. She also outlined the payment options, including a 30% advance deposit and the remaining balance upon production finish confirmation, which aligned with Mr. Mitchell’s company’s procurement policies. Two weeks later, Mr. Mitchell received the sample via DHL. His team conducted rigorous testing, confirming the tungsten’s purity exceeded 99.95% and its dimensional accuracy matched the specifications. Satisfied, he placed the full order and made the advance deposit through the website’s secure payment portal. Throughout the production process, Lisa provided weekly updates, including photos of the manufacturing line and progress reports—something Mr. Mitchell noted was “unheard of with previous suppliers.” When the order was shipped, TUNGSTENBUY provided a detailed packing list and DHL tracking number, allowing Mr. Mitchell to monitor the shipment in real time. The 500 tungsten rods arrived in Seattle exactly 10 days later, packed in

Beyond Price: The Ultimate Guide to Choosing Your Titanium Supplier & Parts Manufacturer

In the world of advanced materials, few metals command the respect of titanium. Its unparalleled strength-to-weight ratio, exceptional corrosion resistance, and biocompatibility make it the material of choice for mission-critical applications in aerospace, medical, chemical processing, and beyond. But sourcing this remarkable material comes with a critical challenge: selecting the right partner. Your choice of a titanium material supplier or a titanium parts manufacturer will directly impact your project’s quality, timeline, and budget. How do you navigate this complex landscape and find a supplier you can trust? This guide provides a strategic framework to help you look beyond the price tag and evaluate potential partners on the criteria that truly matter. The First Step: Understanding Your Need – Supplier vs. Manufacturer Before you begin your search, it’s crucial to distinguish between two primary types of partners, as your needs will dictate who you should approach. Many of the most valuable partners, however, are vertically integrated—acting as both expert suppliers and manufacturers. This offers a seamless, single point of contact from raw material sourcing to final part delivery, ensuring quality control throughout the entire process. The 5 Key Pillars for Evaluating a Titanium Partner Whether you are sourcing raw stock or custom components, use these five pillars to build your evaluation scorecard. Pillar 1: Deep Technical Expertise & Material Mastery A great partner doesn’t just sell metal; they provide solutions. Can they intelligently discuss the pros and cons of different titanium alloys for your specific application? Pillar 2: Verifiable Quality Control & Certifications For high-performance materials like titanium, quality is non-negotiable. Traceability from the raw material ingot to the final part is essential. Pillar 3: Proven Manufacturing & Processing Capabilities If you need finished parts, look for concrete evidence of their manufacturing prowess. Pillar 4: Robust Supply Chain & Global Export Experience A reliable supply chain ensures your project stays on schedule. For international buyers, a partner with extensive export experience is critical. Pillar 5: A True Sense of Partnership & Communication Is the supplier responsive? Are they willing to engage with your engineering team to solve problems? A low price from an uncommunicative supplier can quickly become very expensive. Why Choose FOTMA as Your Strategic Titanium Partner? Now that you have the framework for evaluation, allow us to demonstrate how we measure up. At FOTMA, we are more than just a name on a list of titanium material suppliers. We

What Do Copper And Nickel Make?

Under certain conditions, copper and nickel can be mixed to form a copper-nickel alloy, which possesses unique physical and chemical properties and is widely utilized across various industrial fields. 1. Basic Properties of Copper and Nickel 2. Mixability of Copper and Nickel Copper and nickel can be effectively mixed under specific conditions, with the core process based on the melting and solidification of metals: It is worth noting that copper and nickel also have a certain degree of solubility in the solid state, enabling the formation of a continuous solid solution. This property serves as an important foundation for the stable formation of alloys between the two. 3. Properties of Copper-Nickel Alloys Copper-nickel alloys combine the advantages of both copper and nickel while also possessing their own unique properties, mainly including: Good Fatigue Resistance: Under long-term cyclic loads, copper-nickel alloys are not prone to fracture due to fatigue. This property makes them perform well in the manufacturing of high-speed rotating mechanical parts (such as bearings and gears). Comprehensive Mechanical Properties: Inheriting the high strength of nickel and the ductility of copper, the alloy not only has sufficient strength to withstand loads (such as mechanical stress and pressure) but also can be easily processed into complex-shaped parts through forging, rolling, casting, and other methods. Excellent Corrosion Resistance: Compared with pure copper, the corrosion resistance of copper-nickel alloys (especially in harsh environments such as seawater, humid air, and industrial waste gas) is significantly improved. For instance, copper-nickel alloys with a nickel content of approximately 30% (e.g., Alloy B10) are commonly used anti-corrosion materials in marine engineering. Stable Electrical and Thermal Conductivity: Although the electrical and thermal conductivity of copper-nickel alloys is slightly lower than that of pure copper, they still maintain a relatively high level. Moreover, their performance is less affected by temperature changes, making them suitable for scenarios requiring high stability of electrical conductivity (e.g., precision resistance components). 4. Influence of Mixing Conditions on Alloy Properties The mixing conditions of copper and nickel (especially the composition ratio and preparation process parameters) have a significant impact on the properties of the final alloy, which is specifically reflected in the following aspects: 5. Applications of Copper-Nickel Alloys Relying on their excellent comprehensive properties, copper-nickel alloys are widely used in various industrial fields, with main application scenarios including: When purchasing copper-nickel alloy products (such as copper nickel alloy tubing or 70 30 copper nickel alloy),

INTERESTED IN JOINING OUR TEAM?

Fill out the form below and someone from our team will be in touch with you!

JOIN OUR NEWSLETTER

Sign up to see our newest products and exclusive offers!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074