Case Study

Titanium Alloy Materials: Properties, Applications, and Sourcing

As a non-ferrous metal materials engineer who has spent more than 30 years in mills, labs, and on customer floors, I have watched titanium alloys earn their place the hard way, part by part and test by test. They pair low density with real strength, shrug off harsh environments, and behave well in the body, which is why engineers, designers, and procurement specialists keep coming back to them for high-stakes work. Here is how I think about their properties, where they excel, and what to lock down when sourcing. Understanding the Unique Characteristics of Titanium Alloy Materials Titanium alloys bring a rare mix of attributes that make them indispensable in high-performance engineering. Those traits come from titanium’s base behavior and the deliberate use of alloying elements. Let’s anchor the fundamentals that define these materials. 1. What Defines Titanium Alloys and Their Composition? Titanium alloys are metallic materials built on a titanium base with additions such as aluminum, vanadium, molybdenum, and tin to tune mechanical and chemical response. These additions preserve titanium’s low density and lift strength, ductility, and high-temperature performance. Composition drives microstructure, and microstructure sets the mechanical behavior. A classic example is Ti-6Al-4V, which contains 6% aluminum and 4% vanadium and delivers a well-balanced mix of strength, ductility, and corrosion resistance. 2. Exploring the Superior Strength-to-Weight Ratio of Titanium Alloys The strength-to-weight ratio is the headline. Relative to their low density, titanium alloys carry high tensile strength and fracture toughness. Titanium is about 40% lighter than steel while offering comparable, sometimes higher, strength. In weight-sensitive sectors like aerospace and automotive, that translates into better fuel efficiency and performance. The net effect is thinner, lighter components that still meet structural requirements. 3. How Titanium Alloys Achieve Exceptional Corrosion Resistance Titanium alloys resist corrosion because they quickly form a stable, protective oxide layer in oxygen-containing environments. This adherent film, primarily titanium dioxide (TiO2), blocks further oxidation or chemical attack. It holds up in seawater, chlorine solutions, and many acids, which is why these alloys are trusted in marine, chemical processing, and medical settings where material loss can be unforgiving. 4. The Biocompatibility of Titanium Alloys for Medical Applications Titanium alloys are biocompatible. They are non-toxic and do not trigger adverse reactions in the body, largely due to the inert oxide layer that limits metallic ion release into tissue. That is why they are standard for implants, surgical instruments, and prosthetics. Their

Top Titanium Alloy Manufacturers: Your Guide to Quality Suppliers

Selecting a titanium alloy manufacturer is a decision I never take lightly. After thirty years reading melt logs, walking shop floors, and debugging specs with procurement teams and design engineers, I have a feel for what separates dependable mills from the ones that create headaches. The aim here is simple, help procurement managers, engineers, and R&D professionals zero in on suppliers that consistently meet tight performance targets and certification requirements, understand where titanium alloys deliver their value across industries, and show how a partner like Hubei Fotma Machinery Co., Ltd. fits into that picture. Understanding the Critical Role of Titanium Alloy Manufacturers in Modern Industries Titanium alloys sit at the heart of many high-tech programs because of their blend of high strength-to-weight ratio, standout corrosion resistance, and biocompatibility. Compared to traditional metals, they enable designs that are lighter without giving up integrity. Manufacturers do more than melt and ship, they enable progress by delivering materials that hold up under extreme conditions and stay reliable in mission-critical work. 1. The growing demand for high-performance titanium alloys Demand keeps climbing. Aerospace, medical, and chemical processing are asking for alloys that last longer in harsh environments, trim weight, and reduce lifecycle cost. That push fuels ongoing work on fatigue resistance, temperature capability, and machinability. On my side of the desk, this shows up as more requests for tighter fatigue data, higher service temperature envelopes, and machining feedback tied to specific heat treatments. 2. Key industries relying on advanced titanium materials Aerospace relies on titanium for structures, engines, and landing gear where low mass and high strength are non-negotiable. The medical sector uses titanium alloys in implants, surgical instruments, and prosthetics, leveraging biocompatibility and corrosion resistance. Chemical processing turns to titanium for heat exchangers, tanks, and piping systems when aggressive media are involved. You will also see titanium in marine, automotive, and sports equipment programs where that same property set pays off. Essential Criteria for Selecting a Reliable Titanium Alloy Manufacturer Picking the right supplier means checking more than a datasheet. Consistency, delivery performance, and the ability to meet specific project requirements matter just as much as headline properties. I prioritize manufacturers with proven technical depth, tight quality control, and a supply chain that holds up under pressure. 1. Evaluating manufacturing capabilities and technological expertise Quality and performance start with capability. Review melting, forging, rolling, and machining assets, then look at how they control

Titanium Alloy Bars: Properties, Applications, and Supplier Expertise

As a non-ferrous materials engineer, I have a soft spot for metals that pull more than their weight, and titanium alloy bars have earned that trust on shop floors and test rigs alike. They combine high strength with low density, shrug off corrosion, hold up under heat, and play nicely with the human body, which is why they show up everywhere from aircraft and race engines to chemical plants and orthopedic implants. Below, I walk through what makes these alloys tick, how grades like Ti-6Al-4V fit into real projects, where they deliver the most value, and how careful manufacturing and quality control, the kind we run at Hubei Fotma Machinery Co., Ltd., determines whether a bar becomes a reliable component or a costly headache. Understanding the Unique Advantages of Titanium Alloy Bars in Modern Industries 1. What makes titanium alloy bars a superior material choice? Titanium alloy bars sit at the intersection of smart alloying and a favorable atomic structure, which together unlock a set of properties many conventional metals cannot match. The headline advantage is the strength-to-weight ratio. You get steel-like structural integrity at nearly half the density, which is a big deal anywhere weight is money or performance, and often both. They also resist corrosion in media that punish lesser materials, including seawater, chlorine, and a range of industrial chemicals. A passive oxide film forms on the surface and self-heals if disturbed, so the material keeps its protective skin even after scratches or wear. That means longer service life, fewer interventions, and less unplanned downtime. Add to that solid strength retention at elevated temperatures, where aluminum alloys tend to drop off, and you have a lightweight option that stays dependable when the heat is on. Biocompatibility is another pillar. Titanium alloys are non-toxic and non-reactive in contact with tissues, which is why they are trusted in medical and dental implants. A low coefficient of thermal expansion and good fatigue resistance round out the durability picture, especially under cyclic loads and temperature swings. Net result, titanium alloy bars deliver a rare mix of lightness, strength, corrosion resistance, thermal stability, and biological compatibility. 2. Overcoming material challenges with titanium’s strength-to-weight ratio When every gram matters, titanium’s strength-to-weight ratio solves problems that heavier metals create. In aerospace, shedding structural mass cuts fuel burn and unlocks payload or range, so a lighter airframe or engine assembly directly impacts mission flexibility and operating

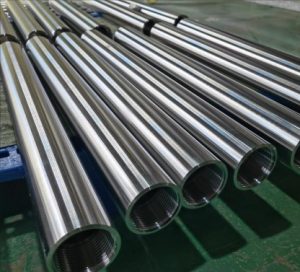

Threaded Titanium Tubes: Properties, Applications, and Manufacturing

Threaded titanium tubes have earned our respect the hard way, on test stands and in the field, where weight needs trimming but performance cannot blink. Their mix of strength, corrosion resistance, and low mass solves problems across aerospace, chemical processing, marine, medical, energy, and automotive work. Drawing on decades in non-ferrous metals, especially titanium, we break down what makes these tubes tick, how the threads are made right, where they thrive, and why they so often end up as the smart choice in high-performance systems. Understanding the Unique Advantages of Threaded Titanium Tubes Titanium and its alloys bring a set of traits that stand apart from typical engineering materials, and threading those tubes multiplies the utility. The headline benefits remain the same every time we spec them in: a high strength-to-weight ratio, excellent corrosion resistance, and real biocompatibility. That combination makes them a natural fit where uptime, reliability, and service life matter. Material Properties of Titanium Alloys Titanium alloys fall into alpha, alpha-beta, and beta families, each with its own mechanical profile. Ti-6Al-4V, the workhorse alpha-beta alloy, blends high strength with useful ductility and weldability. Pure titanium grades, such as Grade 2 and Grade 5, exhibit varying levels of strength and formability. The best alloy choice always comes back to operating conditions, including temperature range, pressure, and chemical media. We often specify titanium alloys for their: 1. High Strength-to-Weight Ratio: Titanium is approximately 40% lighter than steel but offers comparable or superior strength. This weight reduction is vital in aerospace and automotive industries. 2. Exceptional Corrosion Resistance: Titanium forms a passive oxide layer that provides excellent resistance to a wide range of corrosive media. This includes seawater, chlorine, and various acids and alkalis. 3. Biocompatibility: Certain titanium grades are non-toxic and non-allergenic, making them suitable for medical implants and pharmaceutical equipment. 4. Excellent Fatigue Resistance: Titanium alloys maintain their structural integrity under cyclic loading, extending component lifespan in dynamic environments. 5. High-Temperature Performance: Many titanium alloys retain significant strength at elevated temperatures, which is vital for aerospace engine components. Consider the specific grade of titanium for your application. For example, Grade 2 is commercially pure and offers good corrosion resistance and ductility, while Grade 5 (Ti-6Al-4V) provides higher strength. The Role of Threads in Titanium Tubing Adding threads to titanium tubes turns a strong material into a modular, service-friendly component. Done right, threads enable tight, leak-resistant joints and controlled adjustability,

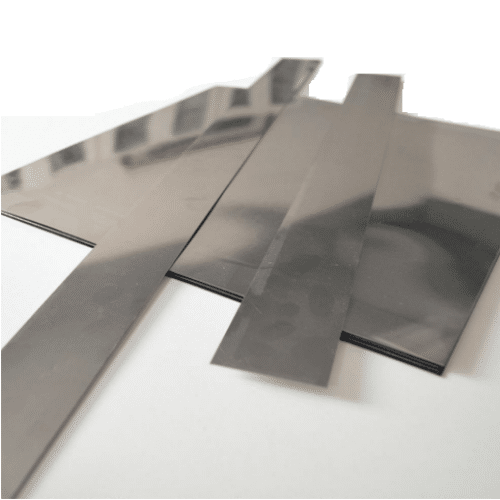

Exploring Thin Tungsten Sheets: Properties, Uses, and Sourcing

After years of speccing high-heat hardware and negotiating buys, I have learned that thin tungsten sheets can make or break a build. When the environment runs hot, heavy, or unforgiving, tungsten’s behavior is predictable, and that reliability matters. My team digs into material science so our clients get exactly what they asked for, from tolerance to texture. What follows is a clear look at thin tungsten sheets, their properties, where they shine, and how to source them without surprises. Understanding the Unique Characteristics of Thin Tungsten Sheets 1. What makes tungsten an exceptional material for thin sheet applications? Tungsten stands out because of how its properties stack together for thin sheet work. The headline is its melting point, approximately 3422°C, the highest among metals, which keeps structures intact in intense heat. Its density is nearly twice that of lead, so you get serious mass in limited volume for inertia or radiation shielding. The strength-to-weight ratio holds up at elevated temperatures, which supports robust, lighter designs when every gram matters. It also brings solid electrical and thermal conductivity for electronics and thermal management. The low coefficient of thermal expansion (CTE) minimizes thermal stress and distortion in precision parts. Taken together, these traits make tungsten a go-to in high-performance applications where failure is not an option. 2. How do purity levels and manufacturing processes influence tungsten sheet properties? Purity and process drive how a thin tungsten sheet behaves. At 99.95% purity or greater, you see better ductility at lower temperatures and improved electrical conductivity. Even small impurities can trigger embrittlement, reduce thermal conductivity, and weaken creep resistance. Powder metallurgy followed by rolling or forging governs grain structure and final performance. Cold rolling adds work hardening, which boosts strength and hardness while cutting ductility. Annealing can recrystallize the sheet to bring ductility back, though strength may drop. Tight control of these steps lets us tune tensile strength, elongation, and surface finish to the application. I always ask for the full processing history, because that trail explains how the material will perform under load and heat. 3. What are the typical physical and chemical properties of thin tungsten sheets? Thin tungsten sheets come with a distinct property set that suits specialized work. Tungsten has an atomic number of 74 and an atomic weight of 183.84 g/mol. Its density is approximately 19.25 g/cm³, among the highest for engineering metals. The melting point is 3422°C and

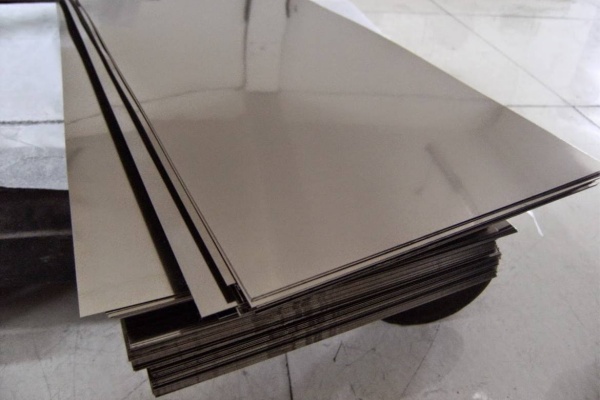

Unveiling the Versatility of Thin Titanium Sheets

Thin titanium sheets sit right at the intersection of weight targets, corrosion challenges, and reliability, which is exactly where most of my customer calls land. As an after-sales engineer, I am often asked to weigh strength against mass, or durability against harsh media, and thin titanium has a way of ticking those boxes with less compromise than most materials. What follows is the same set of practical checks and field-proven insights I use when helping engineers and buyers make confident, high-performance choices. Understanding the Unique Attributes of Thin Titanium Sheets 1. What makes titanium an exceptional material choice Titanium earns its place on the shortlist because of its standout strength-to-weight ratio. It comes in significantly lighter than steel while delivering comparable or better strength, which matters when every gram counts. It also resists corrosion impressively, especially against chlorine, saltwater, and many industrial chemicals, so components last longer in punishing environments. Add its biocompatibility, the body accepts it without adverse reactions, and it becomes a natural fit for medical use. Put together, these traits make titanium a go-to for specialized engineering problems where performance margins are narrow. 2. Exploring the key properties of thin titanium sheets Thin titanium sheets hold the same core advantages of titanium but open up design flexibility. Reduced thickness magnifies the strength-to-weight benefit, so structures get lighter without surrendering integrity. Corrosion resistance remains intact, delivering durable service in tough conditions. They form well, which helps when complex shapes or tight radii are on the drawing board. They also keep their strength at elevated temperatures, which is why aerospace and high-performance automotive teams value them. The net result is a material format that enables more ambitious designs with fewer trade-offs. 3. How manufacturing processes influence sheet quality and performance Manufacturing routes shape the final performance. Rolling, annealing, and surface treatments determine microstructure and mechanical behavior. Cold rolling raises strength and improves surface finish, while hot rolling handles larger reductions. The anneal needs tight temperature and time control to hit the right balance of ductility and strength. Surface treatments, such as pickling or passivation, help boost corrosion resistance and set the surface for secondary processes or coatings. We keep strict quality gates through each step, which protects the consistency you need at production scale. Diverse Applications Driving Demand for Thin Titanium Sheets 1. Revolutionizing aerospace and defense with lightweight solutions Aerospace and defense lean heavily on thin titanium sheets

Thick Wall Titanium Tubes: Unmatched Strength and Corrosion Resistance

When reliability and safety sit on the line, the choice of metal stops being academic, and thick wall titanium tubes have proven their worth time and again. They marry a standout strength-to-weight ratio with corrosion resistance that holds up under pressure, heat, and harsh chemistry, so systems stay online. Drawing on years in non-ferrous metals, we’ve helped engineers balance specifications, standards, and real-world constraints, which is why we walk through what makes these tubes perform, how they compare to common alloys, where they’re used, how they’re made and tested, and how to pick a supplier that won’t let you down. Understanding the Superior Properties of Thick Wall Titanium Tubes Titanium delivers a rare combination: high strength at low density and corrosion resistance that stands up to aggressive media. Build it into thick wall tubes and those advantages compound, yielding greater rigidity and longer service life in punishing conditions. 1. What makes titanium an ideal material for demanding applications Titanium’s appeal comes from its metallurgy. Its density is roughly 60% of steel, yet its tensile strength can rival or exceed many steel alloys, which lets you reduce weight without sacrificing structural integrity. When exposed to oxygen, it forms a passive oxide layer, a tight, self-healing film that resists a wide range of aggressive chemicals, including chlorides, acids, and seawater. That passive layer underpins titanium’s longevity in corrosive environments. The metal also offers excellent fatigue resistance, so it endures repeated stress cycles under dynamic loads. It is biocompatible as well, which makes it suitable for medical and biomedical applications where it contacts human tissue. 2. The critical advantages of thick wall construction for enhanced durability Thick wall construction elevates the performance of titanium tubes in high-pressure or high-stress service. Added wall thickness increases burst strength, improves resistance to external pressure, and boosts structural rigidity. This matters in fluid transport at extreme pressures and anywhere the tube doubles as a structural member. The extra material also buys margin against erosion, abrasion, and localized corrosion, extending service life. In deep-sea oil and gas operations, for example, thick wall titanium tubes stand up to internal and external pressures while facing highly corrosive seawater and aggressive hydrocarbons. That robustness lowers the risk of catastrophic failure, supports operational safety, and trims maintenance downtime. 3. Comparing titanium’s performance with traditional industrial metals Against traditional options like stainless steel and nickel alloys, titanium’s strengths stand out. Stainless steels handle

Understanding Tantalum Tungsten Alloys: Properties and Applications

As an after-sales engineer, I’ve lost count of the times a field failure traced back to materials pushed past their limits—think furnace components warping mid-run or rocket hardware eroding faster than expected. In those moments, tantalum tungsten alloys have been the quiet hero: strong when it’s blisteringly hot, unfazed by harsh chemicals, and still workable enough to machine or form. The trick is knowing exactly which blend fits the job. In this piece, I’ll walk through what makes these alloys tick, where they shine, and how thoughtful selection can boost reliability and keep operations running smoothly. Exploring the Unique Composition and Characteristics of Tantalum Tungsten Alloys 1. Defining Tantalum Tungsten Alloys and Their Metallurgical Significance Tantalum tungsten alloys are refractory metal systems built around tantalum (Ta) and tungsten (W). Each brings a distinct edge: tantalum delivers outstanding corrosion resistance and ductility, while tungsten contributes exceptional high-temperature strength and wear resistance. By tuning the Ta/W ratio, engineers can dial in property trade-offs for a given use case. Metallurgically, their value lies in holding shape and performance at temperatures that would quickly overwhelm most conventional materials. 2. Key Physical and Chemical Properties of Tantalum Tungsten Alloys Tantalum tungsten alloys pack a rare combination of properties: very high melting points, excellent strength at elevated temperatures, and remarkable resistance to chemical attack. They also offer solid thermal conductivity and relatively high density. As tungsten content goes up, you generally gain strength and hardness while giving up a bit of ductility—useful levers when balancing design needs. Property Tantalum (Pure) Tungsten (Pure) Tantalum-Tungsten Alloy (e.g., Ta-10W) Unit Melting Point 3017 3422 ~3000-3300 °C Density 16.6 19.25 ~16.8-18.5 g/cm³ Tensile Strength (RT) ~200-400 ~1000-1500 ~500-800 MPa Electrical Resistivity 13.1 5.6 ~10-12 nΩ·m Thermal Conductivity (RT) 57.5 173 ~60-100 W/(m·K) Corrosion Resistance Excellent Good Excellent – Ductility High Low Moderate to High – 3. How Tantalum and Tungsten Contribute to Alloy Performance Tantalum’s strengths center on corrosion resistance and biocompatibility, thanks to its stable, protective oxide layer—even in aggressive acids. Tungsten brings the highest melting point of any metal and retains strength deep into high-temperature service. In tandem, tantalum’s ductility tempers tungsten’s brittleness, while tungsten bolsters tantalum under heat and load. The result is a tough, balanced alloy built to handle extreme thermal, mechanical, and chemical stress. Unveiling the Advanced Applications of Tantalum Tungsten Alloys Across Industries Tantalum tungsten alloys earn their keep wherever failure isn’t an option.

Exploring the Strongest Tungsten Alloys for Extreme Applications

The first time I picked up a tungsten counterweight, I remember thinking how improbable it felt—so compact, yet unmistakably dense and purposeful. That same combination of strength, density, and high-temperature resilience is why tungsten alloys keep showing up wherever conditions get unforgiving. Here, we look at what makes tungsten and its alloys special, how high-density and tungsten–copper systems are engineered and used, and what to weigh up when selecting the right grade. Along the way, I’ll share where these materials shine in real-world aerospace, medical, electronics, and tooling environments—and how careful manufacturing and quality control translate into reliable performance. Understanding the Unique Properties of Tungsten and Its Alloys Tungsten stands out among metals for its extraordinary characteristics. These properties make it indispensable in applications where other materials fail. We delve into its inherent attributes and how alloying further enhances its capabilities. 1. The inherent strength and density of pure tungsten Pure tungsten possesses the highest melting point of all metals, reaching an astounding 3,422°C (6,192°F). This makes it a natural fit for high-temperature environments. With a density of approximately 19.3 g/cm³—on par with gold—it delivers substantial mass in a small footprint, which is why it performs so well in weight-critical or radiation-shielding roles. It also offers remarkable tensile strength and hardness, holding its shape under intense stress. The trade-off, however, is brittleness at room temperature, which limits the direct structural use of pure tungsten in many applications. 2. How alloying elements enhance tungsten’s performance To counter pure tungsten’s room-temperature brittleness—and to fine-tune other properties—engineers introduce alloying elements. The result is a more balanced blend of strength, ductility, and targeted functionality. For example, nickel, iron, and copper are common binders in tungsten heavy alloys, improving machinability and ductility while preserving high density and strength. In other formulations, copper is added to boost thermal and electrical conductivity, enabling specialized composites. Getting the composition right is critical, as it governs the final properties and determines where each alloy excels. High-Density Tungsten Alloys: Unrivaled Strength and Performance High-density tungsten alloys (WHAs) represent a pinnacle in material science. They combine tungsten’s exceptional density with improved mechanical properties. These alloys are crucial for applications demanding both strength and significant mass. 1. Composition and manufacturing of tungsten heavy alloys (WHA) High-Density Tungsten Alloy (WHA / Tungsten Heavy Alloy) typically consist of 85–97% tungsten, with the remaining percentage comprising binder elements such as nickel and iron (Ni-Fe) or

INTERESTED IN JOINING OUR TEAM?

Fill out the form below and someone from our team will be in touch with you!

JOIN OUR NEWSLETTER

Sign up to see our newest products and exclusive offers!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074