High-Silicon Aluminum Alloy

|

Property |

High-Silicon Aluminum Alloy | Aluminum Silicon Carbide (AlSiC) |

| Density | 2.4~2.7 g/cm³ (lighter) |

2.8~3.1 g/cm³ |

|

Thermal Conductivity |

100–160 W/m·K | 160–200 W/m·K (superior) |

| CTE Adjustability | 7–20 ppm/°C |

6–12 ppm/°C (closer to semiconductor CTE) |

|

Strength |

Moderate-high (light/medium loads) | Ultra-high (impact-resistant, heavy-duty) |

| Ideal Applications | Portable devices, mid-power systems |

Defense, aerospace, high-power electronics |

High-Silicon Aluminum Alloy and Aluminum Silicon Carbide (AlSiC) – Advanced Solutions for Electronic Packaging and Thermal Management

High-Silicon Aluminum Alloy: Perfect Balance of Lightweight Design and Thermal Control

Material Characteristics

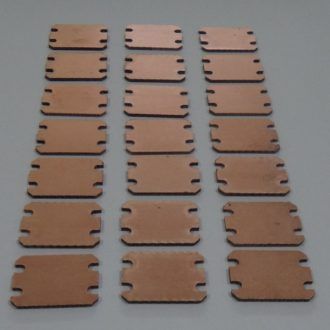

High-Silicon Aluminum Alloy is a binary alloy composed of silicon (Si) and aluminum (Al). By adjusting silicon content (typically 50%–80%), it combines silicon’s high strength and low thermal expansion with aluminum’s lightweight and high thermal conductivity, making it an advanced material engineered for high-tech electronic packaging and aerospace applications.

-

Lightweight Design: Density of 2.4–2.7 g/cm³, significantly lower than traditional metals like copper or steel, enabling weight reduction in aerospace systems and portable electronics.

-

Adjustable Thermal Expansion Coefficient (CTE): CTE range 7–20 ppm/°C. Increasing silicon content reduces CTE values, ensuring precise compatibility with chips, ceramics, and other critical components.

-

Superior Integrated Performance:

-

Thermal conductivity: 100–160 W/m·K for efficient heat dissipation;

-

High specific strength and stiffness exceeding magnesium and titanium alloys, with excellent creep resistance;

-

Surface compatibility with gold, silver, copper, and nickel plating, alongside superior weldability and precision machining capabilities.

-

Applications

-

Aerospace: Satellite electronic packaging, thermal control structures, inertial navigation systems;

-

High-Performance Electronics: 5G RF module housings, CPU/GPU packaging bases, high-power LED heat sinks;

-

Portable Devices: Ultra-thin laptop heat spreaders, drone motor cooling assemblies.

Technical Advantages

-

Custom Silicon Content: Tailor alloy ratios to balance CTE and mechanical properties for specific applications.

-

Precision Machining: Directly mill, drill, or polish into complex geometries, reducing post-processing costs.

Aluminum Silicon Carbide (AlSiC): A Revolutionary Leap in Strength and Thermal Efficiency

Material Innovation

Aluminum Silicon Carbide (AlSiC) is a ceramic-reinforced aluminum matrix composite fabricated via vacuum pressure infiltration. Molten aluminum is forced into porous SiC preforms, forming a 3D interpenetrating structure that drastically enhances mechanical and thermal properties.

Core Properties

-

Ultra-High Strength and Stiffness:

Flexural strength ≥350 MPa, hardness up to HRB 85—2–3x higher than traditional aluminum alloys;

Elastic modulus 220–260 GPa, rivaling titanium alloys for exceptional deformation resistance. -

Advanced Thermal Management:

Thermal conductivity 160–200 W/m·K, matching pure aluminum for rapid heat dissipation;

Tunable CTE range of 6–12 ppm/°C, ideal for GaAs, AlN, and other semiconductor interfaces. -

Extreme Environment Resilience:

Resists corrosion, radiation, and temperatures exceeding 300°C, ensuring reliability in harsh conditions.

Applications

-

Defense & Aerospace: Missile guidance system housings, spacecraft power modules;

-

Power Electronics: IGBT/DBC substrates, EV motor controller cooling plates;

-

Optoelectronics: Laser diode heat sinks, fiber-optic device encapsulation.

Process Advantages

-

Near-Net-Shape Fabrication: Pre-form SiC skeletons to customer specifications, minimizing machining waste;

-

Composition Flexibility: Adjust SiC content between 40%–75% to optimize mechanical and thermal performance.

High-Silicon Aluminum Alloy vs. AlSiC: Choosing the Right Solution

| Property | High-Silicon Aluminum Alloy | Aluminum Silicon Carbide (AlSiC) |

|---|---|---|

| Density | 2.4–2.7 g/cm³ (lighter) | 2.8–3.1 g/cm³ |

| Thermal Conductivity | 100–160 W/m·K | 160–200 W/m·K (superior) |

| CTE Adjustability | 7–20 ppm/°C | 6–12 ppm/°C (closer to semiconductor CTE) |

| Strength | Moderate-high (light/medium loads) | Ultra-high (impact-resistant, heavy-duty) |

| Ideal Applications | Portable devices, mid-power systems | Defense, aerospace, high-power electronics |

Why Partner with FOTMA

Space-Certified Quality: Materials tested under NASA and ESA extreme-condition protocols, ensuring top reliability in demanding applications.

End-to-End Engineering Support: From design simulation to mass production, our team provides full-cycle technical assistance, with prototypes delivered in 15 days.

Cost Efficiency: Proprietary AlSiC infiltration technology cuts production costs by 30% compared with global competitors.

Expert Consultation: Our engineers help select the optimal balance between CTE, density, and conductivity, offering tailored thermal management solutions for your specific system.

Trusted Expertise and Proven Performance

With decades of experience in advanced materials for aerospace and electronic packaging, FOTMA delivers not only High-Silicon Aluminum Alloy and AlSiC composites, but also technical confidence. Our ISO-certified production, combined with a global client base in defense and semiconductor industries, positions us as a trusted thermal management materials manufacturer.

From satellites to smartphones, High-Silicon Aluminum Alloy and AlSiC composites redefine performance in precision systems.

👉 Contact FOTMA today to request a free material selection guide or prototype samples. Our experts are ready to help you design the next generation of lightweight, high-efficiency thermal solutions.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074