TZM Alloy Titanium-Zirconium-Molybdenum Alloy

|

Property |

Typical Value | Unit | Remark |

| Chemical Composition | Mo (Base) + Ti (0.40-0.55%) + Zr (0.06-0.12%) + C (0.01-0.04%) | % (by weight) |

Typical range, adjustable upon request |

|

Density |

~10.15 – 10.22 | g/cm³ | Room Temperature |

| Melting Point | ~2620 | °C |

Approx. same as pure Molybdenum |

|

Recrystallization Temperature |

1350 – 1450 | °C |

Depends on processing & composition |

TZM (Titanium-Zirconium-Molybdenum) Alloy: Superior Performance, Leading High-Temperature Applications

TZM alloy (Titanium-Zirconium-Molybdenum alloy) is a molybdenum-based alloy produced through powder metallurgy or vacuum arc-melting processes. It is formed by adding small amounts of titanium (∼0.5%), zirconium (∼0.08%), and traces of carbon (∼0.01−0.04%), resulting in a dispersion-strengthened high-temperature molybdenum-based alloy. Compared to pure molybdenum, TZM molybdenum alloy utilizes the dual effects of solid solution strengthening and carbide dispersion strengthening to significantly improve its high-temperature strength, recrystallization temperature, creep resistance, and hardness. Simultaneously, it retains the inherent advantages of molybdenum, such as a high melting point, high thermal conductivity, and a low coefficient of thermal expansion. This makes molybdenum tzm alloy an ideal structural material for extreme high-temperature and high-stress environments.

Core Performance Advantages of TZM Molybdenum Alloy

- Excellent High-Temperature Strength: TZM alloy maintains considerably high strength and hardness at temperatures up to 1300∘C and even higher, performing significantly better than pure molybdenum and some other high-temperature alloys.

- High Recrystallization Temperature: Its recrystallization temperature is typically around 1400∘C, approximately 250−300∘C higher than that of pure molybdenum. This means the material resists softening and maintains structural stability when used at higher temperatures.

- Superior Creep Resistance: Under high temperatures and prolonged stress, TZM molybdenum alloy exhibits better resistance to plastic deformation, making it suitable for long-term load-bearing high-temperature components.

- High Thermal Conductivity and Low Coefficient of Thermal Expansion: It inherits molybdenum’s excellent thermal conductivity, aiding in rapid heat dissipation. Its low coefficient of thermal expansion ensures good dimensional stability and low thermal stress during drastic temperature changes.

- Good Machinability: Compared to pure molybdenum, molybdenum tzm alloy offers better ductility and workability (e.g., forging, rolling, machining) under certain conditions, although processes suitable for refractory metals are still required.

- Good Corrosion Resistance: It demonstrates good resistance to certain molten metals (like liquid zinc), molten salts, and inert gases.

Available Forms and Specifications

We can supply TZM alloy products in various specifications and forms according to customer requirements, primarily including:

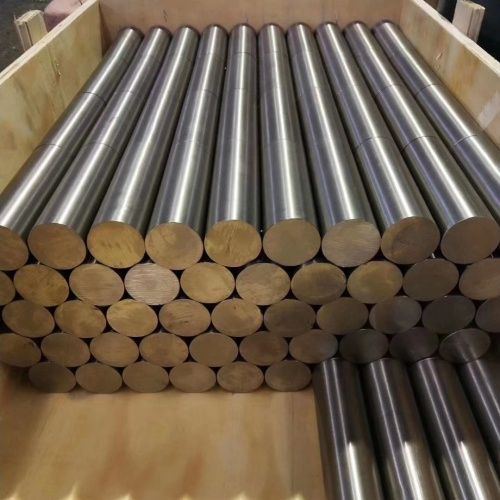

- TZM Rod: Wide range of diameters, used for manufacturing fasteners, shafts, electrodes, etc. We specialize in molybdenum high temperature alloy tzm rod with superior straightness tolerance.

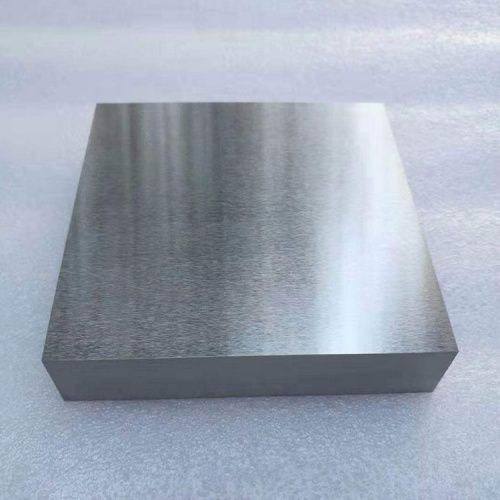

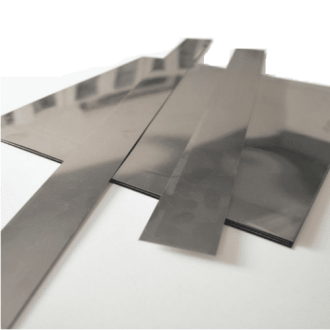

- Plates / TZM Sheet: Various thicknesses available, suitable for heat shields, furnace structural parts, sintering boats, etc. Our production includes precise tzm molybdenum alloy sheet cuts.

- Wires: Used for heating elements in high-temperature furnaces, springs, etc.

- Tubes: Customizable dimensions, used in heat exchangers, piping systems, etc.

- Forgings: Customized according to drawings, used for high-strength, complex-shaped components.

- Custom Parts: Precision machining according to customer-provided drawings and requirements for various non-standard parts.

Surface Finish: Available in various surface conditions, including as-sintered/black, chemically cleaned, alkali washed, ground, and polished. Applicable Standards: Products typically comply with relevant standards such as ASTM B386/B387 (Molybdenum and Molybdenum Alloy Plate, Sheet, Strip, Foil / Bar, Rod, Wire), or can be produced according to specific customer requirements.

TZM Metal Typical Application Fields

Owing to its outstanding high-temperature properties, TZM alloy is widely used in the following fields:

- Aerospace Industry: Rocket engine nozzles, throat liners, gas rudders, missile components, aircraft thermal protection structures, etc.

- High-Temperature Furnace Industry: Heating elements, heat shields, supports, trays, sintering boats, hearth plates, guide rails for vacuum and protective atmosphere furnaces.

- Electronics and Semiconductor Industry: Components for ion implantation equipment, electron tube grids, anodes, sputtering targets, etc.

- Mold Manufacturing: Cores, inserts, and sprue bushings for aluminum, magnesium, and zinc alloy die-casting molds; hot isostatic pressing (HIP) molds; high-temperature hot working dies.

- Glass Melting Industry: Electrodes, stirrers, channels, and other components in contact with high-temperature molten glass in glass furnaces.

- Nuclear Energy Industry: Structural materials for high-temperature reactors.

- Medical Field: Used as X-ray targets or radiation shielding materials.

TZM Alloy Properties

| Property | Typical Value | Unit | Remark |

| Chemical Composition | Mo (Base) + Ti (0.40-0.55%) + Zr (0.06-0.12%) + C (0.01-0.04%) | % (by weight) | Typical range, adjustable upon request |

| Density | ∼10.15−10.22 | g/cm3 | Room Temperature |

| Melting Point | ∼2620 | ∘C | Approx. same as pure Molybdenum |

| Recrystallization Temperature | 1350−1450 | ∘C | Depends on processing & composition |

| Thermal Conductivity | ∼140 (@ 20∘C) | W/(m⋅K) | Room Temperature |

| Hardness | 250−350 (Annealed) | HV | Room Temp., varies with processing state |

| Tensile Strength | 600−900 (Annealed, @ 20∘C) | MPa | Room Temp., significantly higher after work-hardening |

| High-Temp Tensile Strength | ∼350−450 (@ 1100∘C) | MPa | Decreases with temp., but remains high |

Unlocking Extreme Performance: Our Technical Expertise and Guaranteed Quality

Our commitment as a top molybdenum tzm alloy manufacturer is backed by two decades of refractory metal processing. We specialize in producing custom molybdenum high temperature alloy tzm rod and large-format tzm molybdenum alloy sheet that consistently exceeds industry standards.

Proven Expertise in High-Stress Environments: We’ve supplied TZM alloy for numerous critical furnace applications, where the material must endure rapid thermal cycling and continuous 1200∘C operating temperatures. Our proprietary sintering and forging methods ensure the carbide precipitates are optimally dispersed, maximizing the creep resistance—a key factor for extending the lifespan of your hot zone components. This hands-on experience allows us to provide unmatched technical support when selecting the right TZM Rod dimensions or customizing tzm molybdenum alloy foil thickness for specialized electronic targets.

Visualizing Unseen Quality: While you can’t see the TiC and ZrC strengthening particles, you can trust our material integrity. Every plate of tzm molybdenum alloy sheet is ultrasonically tested to ensure zero internal voids or defects, guaranteeing uniform density (10.15g/cm3 minimum) critical for applications like X-ray targets. Furthermore, the surface of our finished TZM Rod is precision ground to a fine, consistent finish, minimizing friction and wear in high-speed, high-stress mechanisms.

Authority Through Data and Traceability: We provide complete batch traceability, confirming the precise percentage of Titanium, Zirconium, and Carbon in your specific order of TZM alloy, aligning perfectly with the property data provided above. All products, including our fine tzm molybdenum alloy foil used in research, come with an internationally recognized Certificate of Analysis (CoA) and adhere strictly to ASTM B386/B387 standards, solidifying our status as an authoritative supplier.

With its unparalleled high-temperature strength, excellent creep resistance, and high recrystallization temperature, TZM alloy has become an indispensable key material in numerous cutting-edge industrial sectors. We are committed to providing high-quality TZM alloy products in various specifications and can offer customized solutions based on your specific application needs. If you are seeking a high-performance material capable of reliable operation under extreme conditions, TZM molybdenum alloy is your ideal choice. Please contact us for more detailed product information and technical support.

Product Certifications

Our TZM Alloy Materials are manufactured in accordance with international quality standards to ensure safety, reliability, and performance. The following certifications apply to this product:

ISO 9001:2015 & SGS:Quality Management System certified

Certification documents are available upon request. To view additional certifications, please contact us.

Trusted by Global Professionals – Real Customers. Real Results.

- Aerospace | Thomas Mitchell (USA)

How an aerospace procurement manager sourced 99.97% pure tungsten rods with custom specs and received delivery in half the expected lead time… Read Full Case Study

- Automotive | Marco Rossi (Italy)

How a car modification expert used custom CNC-machined tungsten alloy weights to fine-tune a vintage sports car’s handling—just in time for a major auto show… Read Full Case Study

- Electronics | Dr. Elena Carter (Canada)

How a semiconductor engineer replaced aluminum with MoCu heat sinks, improving thermal performance by 20°C while meeting aerospace-grade standards… Read Full Case Study

Need Custom Sizes or Bulk Orders?

Contact our engineering team for expert consultation on TZM Alloy Titanium tailored to your specific requirements. We offer OEM and ODM services with fast global shipping.

Frequently Asked Questions

Q1: What is TZM alloy, and why is it used in high-temperature applications?

A1: TZM is a molybdenum-based alloy containing 0.50% titanium, 0.08% zirconium, and 0.02% carbon. It offers superior strength, high-temperature resistance, and excellent creep resistance, making it ideal for aerospace, furnace, and die casting industries.

Q2: What forms of TZM alloy does FOTMA offer?

A2: FOTMA supplies TZM in various forms including:

- TZM rods

- TZM plates and sheets

- Forged bars and customized components

All products are manufactured to exacting standards for precision and performance.

Q3: How does TZM compare to pure molybdenum in performance?

A3: TZM alloy provides:

- Twice the recrystallization temperature

- Higher tensile strength and hardness

- Improved resistance to deformation at elevated temperatures

Compared to pure molybdenum, TZM maintains mechanical properties in extreme environments more effectively.

Q4: What industries commonly use TZM alloy?

A4: TZM is widely used in:

- Aerospace propulsion systems

- High-temperature vacuum furnaces

- Die casting dies and hot runner systems

- Nuclear energy and military applications

Its resistance to thermal fatigue and high structural integrity make it a top material for thermal-intensive applications.

Q5: Can FOTMA manufacture custom TZM alloy parts?

A5: Yes. FOTMA supports OEM and custom fabrication, offering precision machining, CAD-based part design, and small-to-large scale production according to your exact technical drawings or specifications.

CONTACT US NOW TO GET LATEST TZM ALLOY PRICE! Please utilize our detailed inquiry form to connect directly with a senior metallurgist who can provide a comprehensive technical solution and a competitive quote for your next order of TZM Rod or TZM Sheet.

LATEST RECOMMENDED

GET A QUOTE

Send us an Inquiry now to find out more Information and the latest prices,thanks!

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074