ABOUT

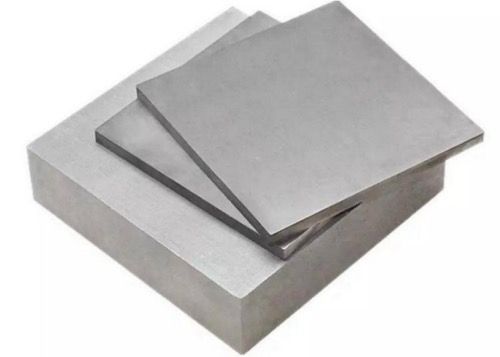

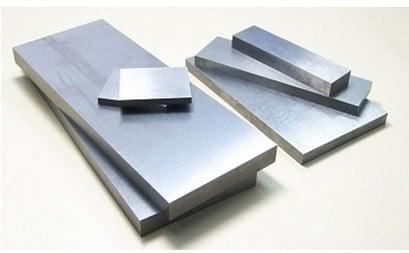

Pure Molybdenum Sheets: Properties, Applications, and Sourcing

As an after-sales engineer, I frequently encounter questions regarding specialized materials for demanding industrial applications. Pure molybdenum sheets consistently emerge as a critical solution due to their exceptional properties. Understanding these characteristics, their diverse applications, and reliable sourcing methods is vital for engineers and procurement specialists. I aim to provide a comprehensive overview to help you make informed decisions for your projects.

Understanding the Unique Characteristics of Pure Molybdenum Sheets

1. What defines pure molybdenum and its key properties?

Pure molybdenum (Mo) is a refractory metal renowned for its exceptional physical and chemical properties. Its purity level typically exceeds 99.95%, making it highly desirable for applications where contamination can compromise performance. Key properties include an extremely high melting point of 2620°C, remarkable high-temperature strength, and excellent thermal and electrical conductivity. Additionally, molybdenum exhibits a low coefficient of thermal expansion (CTE) and good machinability, which are critical for precision engineering. These attributes position pure molybdenum sheets as an indispensable material in various high-tech industries.

2. How does molybdenum’s high melting point benefit industrial applications?

Molybdenum’s exceptionally high melting point, second only to tungsten and tantalum among commercially viable metals, provides significant advantages in industrial applications. This property allows molybdenum sheets to maintain structural integrity and mechanical strength at temperatures where most other metals would soften, deform, or melt. For instance, in high-temperature furnaces, components made from molybdenum can withstand extreme heat without degradation, ensuring operational stability and longevity. This characteristic is crucial for processes like sintering, annealing, and crystal growth, which demand stable environments at elevated temperatures.

3. What are the thermal and electrical conductivity advantages of molybdenum sheets?

Molybdenum sheets offer superior thermal and electrical conductivity, which are essential for many advanced applications. Their high thermal conductivity facilitates efficient heat dissipation, preventing overheating in electronic devices and high-power systems. Simultaneously, their excellent electrical conductivity ensures minimal energy loss and efficient current flow, making them suitable for electrical contacts and heating elements. These combined properties make molybdenum an ideal material for components requiring both efficient heat management and reliable electrical performance, such as in semiconductor manufacturing and power electronics.

If you are interested in the manufacturing process of high-quality molybdenum products, check Manufacturing Process Of High Quality Molybdenum Plate Products.

Exploring Diverse Applications for Pure Molybdenum Sheets Across Industries

1. How are molybdenum sheets utilized in vacuum furnace hot zones?

Molybdenum sheets are extensively used in Vacuum Furnace Heating Chamber and hot zone thermal shields due to their exceptional high-temperature stability and low vapor pressure. In these environments, they form critical components such as heating elements, heat shields, and structural supports. The material’s ability to withstand extreme temperatures without significant outgassing ensures a clean vacuum environment, which is vital for processes like vacuum heat treatment, sintering, and brazing. The longevity and reliability of molybdenum components contribute to the efficiency and cost-effectiveness of these industrial furnaces.

2. What role do molybdenum sheets play in electronic heat sinks and spreaders?

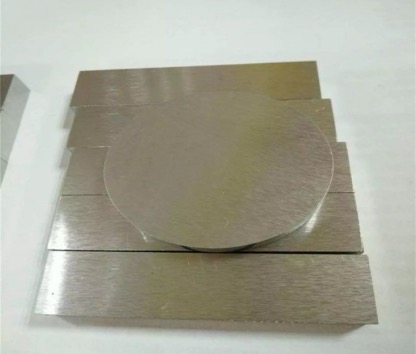

In the electronics industry, molybdenum sheets serve as crucial materials for heat sinks and spreaders. The increasing power density of electronic components necessitates efficient thermal management. Molybdenum’s high thermal conductivity and low coefficient of thermal expansion (CTE), which closely matches that of semiconductors like silicon, prevent thermal stress and warpage. This makes Molybdenum Plate Moly Sheet ideal for applications like Molybdenum Copper Alloy Mocu Heat Sink and igbt heat sink substrates, ensuring reliable performance and extended lifespan for high-power devices.

3. In what ways are molybdenum sheets essential for sputtering targets and X-ray components?

Molybdenum sheets are indispensable in the manufacturing of sputtering targets and X-ray components. As sputtering targets, their high melting point and mechanical stability allow for the deposition of thin, high-purity molybdenum films in semiconductor and display manufacturing. For X-ray tubes, molybdenum’s high atomic number and thermal properties make it an excellent choice for anodes, where it can withstand intense electron bombardment and dissipate heat effectively, producing high-quality X-ray beams for medical imaging and industrial inspection. We also provide Molybdenum Sputtering Targets for these applications.

4. How do molybdenum sheets contribute to aerospace thermal structures and high-temperature tooling?

In aerospace, molybdenum sheets are vital for thermal structures and high-temperature tooling. Their excellent high-temperature strength and creep resistance make them suitable for components exposed to extreme heat, such as rocket nozzles and re-entry vehicle parts. For high-temperature tooling, molybdenum’s hardness and resistance to thermal shock ensure the durability and precision of molds, dies, and fixtures used in hot pressing, forging, and extrusion processes. These properties are critical for manufacturing components that operate under severe thermal and mechanical stresses.

If you want to know more about molybdenum alloys, check What Is Molybdenum Alloy.

Ensuring Quality and Performance in Pure Molybdenum Sheet Manufacturing

1. What are the critical manufacturing processes for high-purity molybdenum sheets?

The production of high-purity molybdenum sheets involves several critical manufacturing processes to ensure material integrity and performance.

1. Powder Metallurgy: Molybdenum powder is pressed into billets. This initial step forms a compact shape from the raw material.

2. Sintering: The billets undergo high-temperature sintering in a controlled atmosphere. This process densifies the material and enhances its mechanical properties.

3. Rolling: The sintered billets are then hot-rolled and cold-rolled into sheets of desired thickness. Rolling refines the grain structure and improves ductility.

4. Annealing: Intermediate annealing steps are performed to relieve internal stresses and prevent cracking. This heat treatment ensures material workability.

5. Surface Treatment: Final surface treatments, such as chemical etching or grinding, achieve the required surface finish and flatness. This ensures the sheets meet precise specifications.

These processes are carefully controlled to maintain the high purity and specific characteristics of the final molybdenum product.

2. How does FOTMA ensure the quality and consistency of its molybdenum products?

FOTMA ensures the quality and consistency of its molybdenum products through stringent quality control measures and advanced manufacturing techniques. We utilize modern production equipment and advanced testing methods throughout our manufacturing process. Our core team’s material research level, backed by over 30 years of technical accumulation, enables us to maintain exceptional standards. We conduct comprehensive material analysis, dimensional inspections, and performance testing to verify that every batch of Molybdenum Plate Moly Sheet meets or exceeds industry specifications and customer requirements. This commitment to quality ensures reliable and high-performing products for our clients.

3. What certifications and standards are important for molybdenum sheet suppliers?

For molybdenum sheet suppliers, adhering to relevant certifications and standards is crucial for demonstrating product quality and reliability. Key certifications often include ISO 9001 for quality management systems, which signifies a commitment to consistent product quality. Material-specific standards, such as ASTM B386 for molybdenum and molybdenum alloy plate, sheet, strip, and foil, define chemical composition, mechanical properties, and dimensional tolerances. Compliance with these standards assures customers of the material’s integrity and suitability for their intended applications, fostering trust and facilitating global trade.

We have an article on the market status and downstream application of China’s molybdenum industry. If you are interested, check Panoramic Analysis Of Chinas Molybdenum Industry In 2025 Market Status And Downstream Application Discussion.

Choosing the Right Pure Molybdenum Sheet for Your Specific Needs

1. What factors should be considered when selecting molybdenum sheet thickness and dimensions?

Selecting the appropriate molybdenum sheet thickness and dimensions requires careful consideration of several factors.

1. Application Requirements: Determine the specific function of the sheet, whether it’s for structural support, heat dissipation, or electrical conduction.

2. Mechanical Stress: Evaluate the anticipated mechanical loads and stresses the sheet will endure. Thicker sheets generally offer greater strength and rigidity.

3. Thermal Management: Assess the heat transfer requirements; thicker sheets can provide better thermal mass, while thinner sheets might be preferred for rapid heat dissipation in certain designs.

4. Fabrication Capabilities: Consider the ease of processing and fabrication for the chosen thickness, as very thin or very thick sheets can present manufacturing challenges.

5. Cost-Effectiveness: Balance performance needs with material costs, as thickness directly impacts the overall price.

Careful evaluation of these factors ensures optimal performance and cost efficiency.

2. How can customized molybdenum sheets meet unique application requirements?

Customized molybdenum sheets can precisely meet unique application requirements by tailoring their properties and dimensions. We offer bespoke solutions, adjusting parameters such as sheet thickness, width, length, and surface finish to match specific design constraints. Furthermore, we can provide specialized heat treatments or surface coatings to enhance particular characteristics, like improved oxidation resistance or specific electrical properties. This customization capability ensures that the molybdenum sheets integrate seamlessly into complex systems, optimizing performance and extending the operational life of the final product.

3. What technical support is available for molybdenum sheet integration?

Comprehensive technical support is available to assist with molybdenum sheet integration into various applications. Our team of experienced engineers provides expert guidance on material selection, design optimization, and fabrication techniques. We offer detailed data sheets, material specifications, and performance characteristics to help clients understand the material’s capabilities. Additionally, we can assist with troubleshooting and provide recommendations for machining, welding, and assembly processes, ensuring successful and efficient integration of pure molybdenum sheets into complex systems.

If you need more information about molybdenum parts, check Custom Molybdenum Parts Processing Molybdenum Screw.

Connect with FOTMA for Your Molybdenum Sheet Needs

FOTMA is a trusted supplier of high-quality pure molybdenum sheets, offering a range of standard and customized solutions. Our extensive experience and commitment to quality ensure that you receive materials perfectly suited to your demanding applications. Whether you require specific dimensions, precise purity levels, or expert technical advice, our team is ready to assist. Contact us today to discuss your project requirements and discover how our molybdenum products can enhance your operations. Reach out to us at +86 13995656368, +86 13907199894, or email bunny@fotma.com, export@fotma.com.

About the Author

Alex Chen is dedicated to ensuring clients receive timely solutions and achieve optimal performance from their products. Passionate about problem-solving and continuous improvement, Alex provides expert insights and practical guidance to help customers maximize the value of their purchases.

FAQs

1. What is the typical purity level of commercial pure molybdenum sheets?

Commercial pure molybdenum sheets typically boast a purity level of 99.95% or higher. This high purity is crucial for applications sensitive to impurities, such as electronics and vacuum furnace components, where even trace elements can significantly affect performance and lifespan. Suppliers often provide detailed material certificates confirming the exact chemical composition.

2. Can pure molybdenum sheets be easily machined or fabricated?

Pure molybdenum sheets can be machined and fabricated, but they require specialized techniques due to their inherent hardness and brittleness at room temperature. Processes like cutting, drilling, and forming are best performed at elevated temperatures to improve ductility and prevent cracking. Laser cutting, EDM (Electrical Discharge Machining), and waterjet cutting are common methods for precise fabrication.

3. What are the primary differences between pure molybdenum and molybdenum alloys?

Pure molybdenum offers excellent high-temperature strength, high melting point, and good thermal/electrical conductivity. Molybdenum alloys, such as TZM (Titanium-Zirconium-Molybdenum) or Mo-La (Molybdenum-Lanthanum Oxide), incorporate small amounts of other elements to enhance specific properties like creep resistance, recrystallization temperature, and ductility, often at the expense of some purity.

4. How do pure molybdenum sheets compare to other refractory metals in high-temperature applications?

Pure molybdenum sheets offer a unique balance of properties compared to other refractory metals. While tungsten has a higher melting point, molybdenum is less dense and generally more machinable. Tantalum offers superior corrosion resistance but is significantly more expensive. Molybdenum provides a cost-effective solution for many high-temperature applications where its specific combination of properties is sufficient.

5. What are the storage and handling recommendations for pure molybdenum sheets?

Store pure molybdenum sheets in a dry, low-humidity environment to prevent oxidation, especially if the surface is unprotected. Handle sheets carefully to avoid scratches or deformation, which can affect their performance in critical applications. For long-term storage, vacuum sealing or inert gas environments are recommended to maintain material integrity.

Table: Comparative Properties of Pure Molybdenum and Other Refractory Metals

| Property | Pure Molybdenum | Tungsten | Tantalum | Niobium |

|---|---|---|---|---|

| Melting Point (°C) | 2620 | 3422 | 3017 | 2477 |

| Density (g/cm³) | 10.2 | 19.3 | 16.6 | 8.57 |

| Thermal Conductivity (W/mK) | 138 | 173 | 57.5 | 53.7 |

| Electrical Conductivity (%IACS) | 31 | 30 | 13.9 | 13.2 |

| CTE (µm/m°C @ 20°C) | 4.8 | 4.5 | 6.5 | 7.2 |

| Hardness (HV) | 150-180 | 350-400 | 80-100 | 60-80 |

| Oxidation Resistance | Poor above 500°C | Poor above 500°C | Excellent | Good |

We Exist to Make Your Projects Successful

Fill out the form below and someone from our team will be in touch with you!

FOTMA Delivers Professional Ultra-Dense Solutions, Lighter on Cost, Heavier on Performance.

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074