ABOUT

Pure Nickel Sheet Metal: Properties, Applications, and Supply

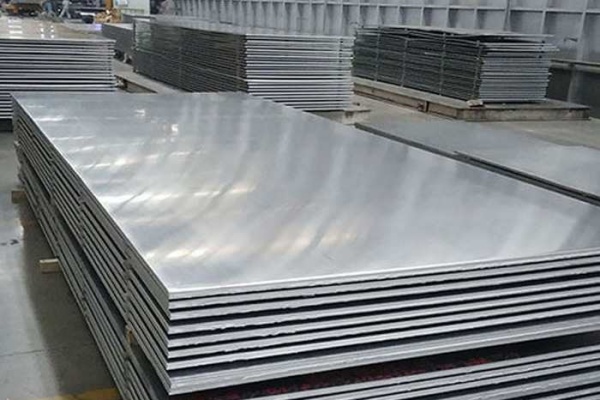

Pure nickel sheet metal offers exceptional properties vital for demanding industrial applications. Its unique combination of corrosion resistance, electrical conductivity, and ductility makes it indispensable across various sectors. We understand the critical need for high-quality materials and aim to provide comprehensive insights into its characteristics, diverse uses, and reliable sourcing. This information helps engineers and procurement managers make informed decisions for their specific project requirements.

Understanding the Unique Characteristics of Pure Nickel Sheet Metal

1. What Defines Pure Nickel Sheet Metal and Its Key Properties?

Pure nickel sheet metal consists primarily of nickel, typically with a purity of 99% or higher. This high purity distinguishes it from nickel alloys, which incorporate other elements to achieve different characteristics. The material’s atomic structure grants it a face-centered cubic lattice, contributing to its excellent ductility and formability. Key properties include outstanding corrosion resistance, particularly in alkaline environments and against various acids. It also exhibits high electrical and thermal conductivity, ferromagnetic properties at room temperature, and good strength at elevated temperatures. These attributes make it highly valuable in specialized industrial contexts.

2. How Does Pure Nickel Sheet Metal Compare to Nickel Alloys?

The primary distinction between pure nickel sheet metal and nickel alloys lies in their composition and resulting properties. Pure nickel, such as Ni200 or Ni201, offers maximum corrosion resistance in specific chemical environments and maintains high electrical conductivity. Nickel alloys, conversely, blend nickel with other elements like chromium, iron, copper, or molybdenum to enhance specific properties. For instance, Inconel alloys excel in high-temperature strength and oxidation resistance, while Monel alloys provide superior resistance to seawater corrosion. The choice between pure nickel and an alloy depends entirely on the application’s specific requirements for strength, temperature, and chemical exposure. For more details on related materials, consider What Do Copper And Nickel Make.

3. What Are the Common Grades and Standards for Pure Nickel Sheet Metal?

Several common grades and international standards govern pure nickel sheet metal, ensuring consistent quality and performance. ASTM B162 specifies the requirements for nickel plate, sheet, and strip, covering grades like Ni200 and Ni201. Ni200 is commercially pure wrought nickel, known for its excellent mechanical properties and corrosion resistance. Ni201 is a low-carbon version of Ni200, preferred for applications above 315°C (600°F) to prevent graphitization, which can lead to embrittlement. Other standards include ASME SB-162, DIN 17750, and ISO 6208, each outlining specific chemical compositions, mechanical properties, and testing procedures. Adhering to these standards guarantees the material meets the stringent demands of critical applications.

Exploring Diverse Industrial Applications of Pure Nickel Sheet Metal

1. How Is Pure Nickel Sheet Metal Utilized in Electronic Components?

Pure nickel sheet metal plays a crucial role in various electronic components due to its excellent electrical conductivity and corrosion resistance. Manufacturers use it extensively for battery components, including battery casings, electrodes, and current collectors, particularly in rechargeable batteries. Its ability to withstand harsh chemical environments and provide reliable electrical contact is paramount. Additionally, it finds application in electrical connectors, lead wires, and shielding for sensitive electronic devices, where its ferromagnetic properties help mitigate electromagnetic interference. The material’s formability also allows for intricate designs required in microelectronics.

2. What Role Does Pure Nickel Play in Chemical Processing Equipment?

In chemical processing, pure nickel sheet metal is indispensable for its exceptional resistance to caustic alkalis and certain acids. It serves as a primary material for constructing reaction vessels, heat exchangers, evaporators, and piping systems. Industries involved in the production of caustic soda, synthetic fibers, and various organic chemicals rely on pure nickel to prevent corrosion and maintain product purity. Its resistance to stress corrosion cracking in chloride-containing solutions further enhances its suitability for these demanding environments. This material ensures the longevity and operational integrity of critical equipment.

3. Where Is Pure Nickel Sheet Metal Essential in Battery Technology?

Pure nickel sheet metal is fundamental to modern battery technology, especially in lithium-ion and nickel-metal hydride batteries. Its high electrical conductivity facilitates efficient charge and discharge cycles, while its corrosion resistance protects internal battery components from electrolyte degradation. We utilize it in battery tabs, cell connectors, and protective casings. The material’s ductility allows for precise stamping and forming into complex shapes required for compact battery designs. These characteristics are critical for ensuring the safety, performance, and lifespan of battery packs in electric vehicles and portable electronic devices.

4. How Does Pure Nickel Sheet Metal Benefit Aerospace and Defense?

The aerospace and defense sectors leverage pure nickel sheet metal for its high-temperature strength, corrosion resistance, and specific magnetic properties. Engineers use it in specialized components for aircraft engines, such as combustion liners and exhaust systems, where it endures extreme thermal and corrosive conditions. Its resistance to oxidation and creep at elevated temperatures ensures structural integrity and operational reliability. In defense applications, pure nickel provides effective electromagnetic shielding for sensitive electronic systems, protecting them from interference in harsh operational environments. Its consistent performance under stress makes it a preferred material for critical aerospace and defense systems.

Ensuring Quality and Sourcing High-Purity Nickel Sheet Metal

1. What Manufacturing Processes Are Used for Pure Nickel Sheet Metal?

The manufacturing of pure nickel sheet metal involves several precise processes to achieve desired properties and dimensions. Initially, high-purity nickel is melted and cast into ingots. These ingots then undergo hot rolling, where they are heated and passed through rollers to reduce thickness and refine grain structure. Subsequent cold rolling further reduces thickness, improves surface finish, and enhances mechanical properties. Annealing steps are often integrated between rolling passes to relieve internal stresses and restore ductility. Finally, the material is cut to specified dimensions and may undergo surface treatments or additional finishing processes to meet application-specific requirements.

2. How to Select a Reliable Supplier for Pure Nickel Sheet Metal?

Selecting a reliable supplier for pure nickel sheet metal is crucial for ensuring product quality and project success. We recommend evaluating suppliers based on their experience, quality certifications (e.g., ISO 9001), and adherence to international material standards. A reputable supplier provides comprehensive material certifications, including chemical analysis and mechanical test reports. They should also offer customization options for dimensions, finishes, and specific purity levels. Furthermore, assess their production capabilities, lead times, and customer support. FOTMA, for example, has over 30 years of experience in non-ferrous metal materials, offering strong technical expertise and advanced testing methods. For more information on choosing a supplier, refer to Beyond Price The Ultimate Guide To Choosing Your Titanium Supplier Parts Manufacturer.

3. What Quality Control Measures Guarantee Product Excellence?

Rigorous quality control measures are essential to guarantee the excellence of pure nickel sheet metal. These measures begin with strict raw material inspection to verify nickel purity and absence of contaminants. Throughout the manufacturing process, we implement in-process checks, including dimensional inspections, surface quality assessments, and non-destructive testing methods like eddy current or ultrasonic testing. Final product testing includes mechanical property evaluations (tensile strength, hardness, ductility) and chemical analysis to confirm composition. Adherence to industry standards and internal quality protocols ensures each sheet meets the precise specifications required for its intended application. This meticulous approach minimizes defects and ensures consistent performance.

Partner with FOTMA for Your Pure Nickel Sheet Metal Needs

At FOTMA, we specialize in providing high-quality pure nickel sheet metal tailored to your exact specifications. With our extensive experience and advanced manufacturing capabilities, we ensure superior material performance for your critical applications. Our team of experts is ready to assist you with technical guidance, custom orders, and reliable supply chain solutions. Contact us today to discuss your project requirements and discover how our pure nickel sheet metal can enhance your products. Reach out to us via email at bunny@fotma.com or export@fotma.com, or call us at +86 13995656368 or +86 13907199894.

About the Author

Alex Chen is dedicated to ensuring clients receive timely solutions and achieve optimal performance from their products. Passionate about problem-solving and continuous improvement, Alex provides expert insights and practical guidance to help customers maximize the value of their purchases.

FAQs

1. What is the primary advantage of pure nickel sheet metal over other metals?

The primary advantage of pure nickel sheet metal is its exceptional corrosion resistance, particularly in alkaline and certain acidic environments. It also offers high electrical and thermal conductivity, good ductility, and ferromagnetic properties. These characteristics make it ideal for applications where chemical inertness and electrical performance are critical, such as in chemical processing and electronics.

2. Can pure nickel sheet metal be customized for specific dimensions or applications?

Yes, pure nickel sheet metal can be extensively customized. Suppliers like FOTMA offer various thicknesses, widths, and lengths to meet specific project requirements. We also provide different surface finishes and can accommodate specialized fabrication processes such as stamping, bending, and welding, ensuring the material integrates seamlessly into diverse applications.

3. What industries most commonly use pure nickel sheet metal?

Pure nickel sheet metal is most commonly used in industries such as chemical processing, electronics, battery manufacturing, and aerospace. Its unique properties, including corrosion resistance, electrical conductivity, and high-temperature strength, are crucial for components in these demanding sectors.

4. How does FOTMA ensure the purity and quality of its nickel sheet metal products?

FOTMA ensures the purity and quality of its nickel sheet metal through rigorous quality control processes. This includes strict raw material inspection, in-process monitoring, and comprehensive final product testing. We adhere to international standards such as ASTM B162 and provide detailed material certifications, guaranteeing high purity and consistent performance.

5. What are the typical lead times for ordering pure nickel sheet metal?

Typical lead times for ordering pure nickel sheet metal vary depending on customization requirements, order volume, and current production schedules. Standard sizes and grades usually have shorter lead times, while highly customized orders may require more time. We recommend contacting our sales team directly for precise lead time estimates based on your specific needs.

We Exist to Make Your Projects Successful

Fill out the form below and someone from our team will be in touch with you!

FOTMA Delivers Professional Ultra-Dense Solutions, Lighter on Cost, Heavier on Performance.

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074