ABOUT

Pure Titanium Sheets: Properties, Applications, and Sourcing

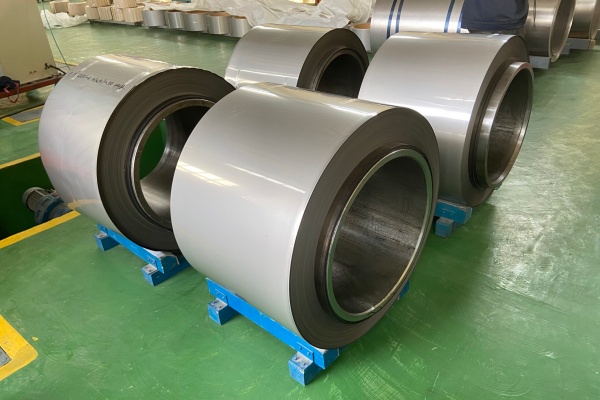

As an after-sales engineer, I’m often the one people call when they’re trying to figure out the best materials for tough industrial jobs. And you know what? Pure titanium sheets pop up in those conversations all the time. It’s not hard to see why—they’ve got this incredible mix of properties that just makes them stand out. For anyone in engineering or procurement, really getting a handle on what makes these sheets tick, where they fit in, and how to find a good supplier is absolutely vital. It can make or break a product’s performance and even a whole project. So, I’m hoping to share some practical insights here, especially for those of you wrestling with specialized materials.

Understanding the Unique Properties of Pure Titanium Sheets

Now, pure titanium might not be as common as some of its alloys in, say, big structural builds, but it brings a whole different set of benefits to the table. Its inherent characteristics make it pretty much indispensable in a lot of cutting-edge industries. We totally get that picking the right material for each specific need is super important.

1. What makes pure titanium an exceptional industrial material?

Pure titanium really shines because it combines a few amazing things: it’s light, strong, and incredibly resistant to corrosion. Think about it: it’s only about 60% as dense as steel, but it can stand up to many common steel grades in terms of strength. That strength-to-weight ratio? That’s gold, especially in aerospace or automotive where every gram counts. Plus, it’s surprisingly ductile, meaning you can form and fabricate it pretty easily, which just adds to its versatility. Oh, and it’s non-magnetic and conducts heat well, which opens up even more possibilities for specialized gear.

2. Exploring the corrosion resistance and biocompatibility of titanium

Titanium’s stellar corrosion resistance is all thanks to this neat trick it pulls: when it touches oxygen, it instantly forms a super stable, passive oxide layer. This tough film acts like a shield, protecting the metal underneath from all sorts of nasty stuff—we’re talking seawater, chlorine, various acids. That’s why it’s a go-to for marine and chemical processing. But wait, there’s more! Titanium’s biocompatibility is truly in a league of its own. The human body just… accepts it. No weird reactions, no rejection. And guess what? That same passive oxide layer is the hero here too, preventing any ions from leaching out and messing with biological systems. This unique inertness is why it’s everywhere in medical and dental implants. Pretty cool, right?

3. Analyzing the strength-to-weight ratio and mechanical advantages

Honestly, the strength-to-weight ratio of pure titanium is one of its biggest selling points. It lets engineers design components that are lighter but just as strong as those made from heavier materials like steel or aluminum. That directly translates to things like better fuel efficiency in planes or snappier performance in high-speed machinery. While pure titanium isn’t quite as strong as some of its alloys, it makes up for it with superior ductility and toughness. That means it’s a bit more forgiving during fabrication and less likely to just snap. And its fatigue resistance? Excellent. You can count on it for long-term reliability even when it’s under constant stress.

Key Grades and Specifications for Pure Titanium Sheets

Choosing the right grade of pure titanium is absolutely crucial if you want optimal performance and to keep costs in check. Each grade has these subtle differences in mechanical properties that really dictate where it’s best used. We always make sure our materials hit those tough industry standards.

If you’re interested, check 《Introduction To Titanium Plates And Titanium Alloy Plates That Are Not Common In Buildings》.

1. Differentiating between commercially pure titanium grades (Grades 1-4)

Commercially pure (CP) titanium comes in four main grades (Grades 1-4), and the differences mostly boil down to their oxygen and iron content. Grade 1 is the softest and most pliable, fantastic for forming and incredibly corrosion resistant. Grade 2 is a step up in strength from Grade 1, still very ductile and easy to weld, which is why it’s the most popular CP grade. Grade 3 gives you even more strength than Grade 2, but you trade off a little ductility. And then there’s Grade 4, the strongest and least ductile of the CP bunch, usually chosen when you need maximum strength at room temperature. Deciding which one to use really depends on finding that sweet spot between strength, ductility, and corrosion resistance for your particular job.

| Grade | Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Primary Characteristics | Common Applications |

|---|---|---|---|---|---|

| Grade 1 | 240 min | 170 min | 24 min | Most ductile, excellent corrosion resistance | Chemical processing, medical devices, architectural |

| Grade 2 | 345 min | 275 min | 20 min | Good balance of strength and ductility, most common | Aerospace, marine, power generation |

| Grade 3 | 450 min | 380 min | 18 min | Higher strength than Grade 2, good weldability | Pressure vessels, surgical implants |

| Grade 4 | 550 min | 485 min | 15 min | Highest strength CP grade, moderate ductility | Airframe components, heat exchangers |

2. Understanding industry standards and certifications for titanium products

Sticking to industry standards and getting the right certifications isn’t just good practice; it’s absolutely essential for making sure titanium products are top-notch and reliable. We’re talking about key specs like ASTM B265 for titanium sheet, strip, and plate, or ISO 5832-2 if you’re making surgical implants. These aren’t just suggestions; they lay out everything from chemical makeup to mechanical properties, dimensions, and how things need to be tested. And when a supplier has certifications like ISO 9001, it’s a solid sign they’re serious about quality management. For aerospace, AS9100 is often a must-have. We take these standards very seriously to guarantee the integrity of every piece of material we handle.

3. How manufacturing processes influence titanium sheet quality and performance

The way a titanium sheet is made really, really affects its final quality and how well it performs. Things like hot rolling, cold rolling, and annealing are common steps. Hot rolling, for instance, not only thins out the ingot but also refines its grain structure, making it stronger. Cold rolling then takes it a step further, giving it a smoother surface and super tight dimensions. And annealing? That’s a heat treatment that basically relaxes the metal, getting rid of internal stresses, boosting its ductility, and optimizing its microstructure. Getting these processes just right—the temperature, how much you reduce it, the annealing cycles—directly impacts the sheet’s strength, how easily it can be formed, and its resistance to fatigue. Sometimes, for extra purity, they even use fancy techniques like vacuum annealing.

Diverse Applications of Pure Titanium Sheets Across Industries

The incredible properties of pure titanium sheets mean they’re perfect for a huge range of demanding applications where other materials just wouldn’t cut it. I’ve personally seen its use grow dramatically across so many different sectors.

If you’re interested, check 《Titanium And Titanium Alloys Widespread Application And Future Challenges》.

1. Utilizing titanium in aerospace and defense for critical components

In aerospace and defense, the high strength-to-weight ratio of pure titanium is just gold. It shaves off so much weight from aircraft and spacecraft, which means better fuel efficiency and more payload capacity. You’ll find it in airframe components, engine parts, and even fasteners. Its amazing corrosion resistance also keeps it safe from environmental damage, which is super important for marine aircraft and anything going into space. And the fact that it can handle extreme temperatures and pressures? That just cements its role in those absolutely critical structural elements.

2. Implementing titanium in medical implants and surgical instruments

Pure titanium’s biocompatibility is, hands down, the biggest reason it’s used so much in medicine. It’s non-toxic and doesn’t trigger an immune response, which makes it perfect for direct contact with human tissue and bone. We’re talking about orthopedic implants like hip and knee replacements, dental implants, surgical tools, and prosthetic devices. The material’s high strength and durability are key to making sure these life-critical components last a long, long time.

3. Applying titanium in chemical processing and marine environments

The sheer superiority of pure titanium’s corrosion resistance makes it a top pick for chemical processing equipment. It just shrugs off attacks from acids, alkalis, and chlorides—all those nasty things you find in chemical plants. This includes heat exchangers, tanks, pipes, and valves. And in marine environments, titanium stands strong against the corrosive onslaught of saltwater and marine organisms, making it ideal for shipbuilding, offshore platforms, and subsea gear. Its resistance to erosion-corrosion is also a huge plus in these really harsh conditions.

4. Exploring emerging applications in consumer goods and renewable energy

It’s not just the big, heavy industries anymore; pure titanium is popping up in new places. In consumer goods, its lightweight nature and hypoallergenic properties are making it a hit in high-end sports gear, jewelry, and watches. People also love its look and durability, which is why it’s showing up in architectural cladding. And in renewable energy, especially geothermal and offshore wind power, titanium’s corrosion resistance and strength are absolutely vital for components that are exposed to aggressive environments. These new uses really show how versatile titanium is and how much more important it’s becoming.

Sourcing High-Quality Pure Titanium Sheets from Reputable Suppliers

Finding good quality pure titanium sheets isn’t something you can just rush into; it really takes careful thought to make sure you’re getting material that’s sound and performs as expected. We always stress being super meticulous when picking a supplier and making sure quality is front and center.

If you’re interested, check 《Beyond Price The Ultimate Guide To Choosing Your Titanium Supplier Parts Manufacturer》.

1. Essential factors to consider when selecting a titanium sheet supplier

When you’re trying to pick a titanium plate suppliers, there are a few things that are absolutely crucial. First, you really need to look at their experience and how well-regarded they are in the industry. A long history and happy clients are usually a good sign they’re reliable. Second, double-check that they actually follow international quality standards and have the right certifications. Third, ask about their manufacturing capabilities—can they handle your specific volume and any custom needs you might have? And finally, don’t forget to check their technical support and after-sales service; for complex projects, that can be a real lifesaver.

2. Ensuring quality control and material traceability for critical applications

For any critical application, top-notch quality control and being able to trace the material back to its origin are non-negotiable. Seriously. Good suppliers will have really thorough quality management systems, which means inspections at every step and final product testing. They’ll also give you detailed material test reports (MTRs) that lay out the chemical composition, mechanical properties, and the entire manufacturing history of each batch. This traceability is key for verifying where the material came from and that it meets all the specs, especially in aerospace and medical fields. We’re super strict with our quality checks, every single step of the way.

3. Customization options and value-added services for titanium sheets

Let’s be real, a lot of projects need specific dimensions, finishes, or even special processing for their titanium sheets. A truly capable supplier will offer customization options like precision cutting, forming, and various surface treatments. And those extra services—like technical advice, help picking the right material, or even logistics support—can seriously smooth out your procurement process. These aren’t just perks; they ensure that what you get isn’t just high-quality, but also perfectly suited for your manufacturing needs.

Contact Us for Your Pure Titanium Sheet Needs

We truly understand how vital high-quality pure titanium sheets are for your industrial applications. Our team at Hubei Fotma Machinery Co., Ltd. is here, ready to offer expert guidance and custom solutions tailored precisely to what you need. With over 30 years of accumulated technical know-how in non-ferrous metals, we’ve got modern production gear and advanced testing methods to guarantee top-notch quality and performance.

Seriously, reach out to us today. Let’s chat about your project and see how our pure titanium sheets can really elevate your products.

Phone: +86 13995656368 | +86 13907199894

Email: bunny@fotma.com, export@fotma.com

About the Author

Alex Chen is all about making sure clients get timely solutions and that their products perform at their absolute best. He’s got a real passion for solving problems and always pushing for improvements, offering expert insights and practical advice to help customers squeeze every bit of value out of their purchases.

FAQs

1. What is the main difference between pure titanium and titanium alloys?

Pure titanium is at least 99% titanium, and it’s fantastic for corrosion resistance and biocompatibility, though it’s not as strong. Titanium alloys, on the other hand, mix in other elements like aluminum and vanadium to boost strength, hardness, and heat resistance. You often trade off a bit of ductility or corrosion resistance for those gains, though.

2. Can pure titanium sheets be easily fabricated or welded?

Pure titanium sheets, especially Grades 1 and 2, are pretty ductile, so they’re relatively easy to form, bend, and deep-draw. Welding pure titanium does require some specific techniques, like using inert gas shielding, to prevent contamination and keep its mechanical properties intact, but generally speaking, it’s considered weldable.

3. What are the typical lead times for custom pure titanium sheet orders?

Lead times for custom pure titanium sheet orders can really vary. It depends on the grade, dimensions, how much you need, and any special processing. Standard sizes and common grades might ship out faster, but highly customized or really large orders could take anywhere from several weeks to a few months. Your best bet is always to just ask the supplier directly for an accurate estimate.

4. How does the cost of pure titanium sheets compare to other high-performance metals?

Pure titanium sheets are generally pricier than everyday industrial metals like stainless steel or aluminum. That’s because the raw materials cost more, the extraction process is complex, and manufacturing requires specialized techniques. However, for critical applications, their superior performance—think corrosion resistance, strength-to-weight ratio, and biocompatibility—often makes that higher initial investment totally worth it.

5. What certifications should I look for when purchasing pure titanium sheets?

When you’re buying pure titanium sheets, you should definitely look for certifications like ASTM B265, ISO 9001 for quality management, and if it’s for aerospace, AS9100 is often a must. These certifications are your assurance that the material meets specific chemical compositions, mechanical properties, and was produced under a controlled, quality-focused system.

We Exist to Make Your Projects Successful

Fill out the form below and someone from our team will be in touch with you!

FOTMA Delivers Professional Ultra-Dense Solutions, Lighter on Cost, Heavier on Performance.

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074