ABOUT

Pure Tungsten Sheets: Properties, Applications, and Sourcing

Pure tungsten sheets are, let’s be honest, pretty remarkable. They’re not just another metal; they’re essential materials in a whole host of high-tech industries, thanks to their truly exceptional properties. I’ve seen firsthand the headaches engineers and procurement folks go through trying to pick out and get their hands on such specialized stuff. So, my goal here is to give you a good, solid rundown on pure tungsten sheets – what makes them tick, where they’re used, and what you really need to think about when you’re making or buying them.

Understanding the Unique Properties of Pure Tungsten Sheets

1. What makes pure tungsten an exceptional material for industrial use

Pure tungsten, among all those tough refractory metals, really stands out. It’s got this unique mix of physical and chemical properties that just can’t be beat. Its atomic structure, believe it or not, is what gives it that incredible strength and keeps it stable even when things get super hot. Honestly, you’ll find it’s indispensable in places where pretty much any other material would just give up the ghost. And, from what I’ve observed, keeping it really pure just cranks up these natural advantages, making sure it performs consistently even in the most demanding situations.

2. Exploring the high melting point and density of tungsten sheets

Okay, so here’s a fun fact: Tungsten has the highest melting point of all metals – we’re talking around 3422°C. That’s just wild, right? This means tungsten sheets can keep their shape and do their job perfectly even at those insane temperatures. And get this: it’s also incredibly dense, almost twice as heavy as steel, and practically in the same league as gold. That high density is a game-changer for things that need a lot of mass packed into a small space, like counterweights or radiation shielding.

3. How tungsten sheets offer superior strength and hardness at elevated temperatures

The very way tungsten’s crystals are structured gives it this amazing strength and hardness, and the best part? It keeps those qualities even when it’s screaming hot. Unlike a lot of metals that just go soft as the temperature climbs, tungsten’s mechanical properties stay rock solid. That’s why it’s perfect for parts that get hit with intense heat and mechanical stress. I’ve personally seen how this performance directly benefits industries like aerospace and those folks making high-temperature furnaces. It’s pretty cool to witness.

4. Examining the excellent electrical and thermal conductivity of pure tungsten

Pure tungsten is also a champ when it comes to conducting electricity and heat. These properties are absolutely crucial for anything that needs to get rid of heat efficiently or carry an electrical current reliably. Its high thermal conductivity means heat gets whisked away fast, stopping sensitive electronics from overheating in one spot. And its electrical conductivity? That’s why it’s used in electrodes and contacts where you absolutely need minimal resistance.

If you’re interested, check 《High Purity Tungsten Wire The Crossover King From Traditional Lighting To Modern Medicine》.

5. Discussing the corrosion resistance and chemical stability of tungsten sheets

You know, tungsten sheets are surprisingly tough against corrosion and pretty stable chemically, especially in really harsh environments. They can shrug off attacks from a lot of acids and alkalis, particularly at room temperature. This chemical inertness, this refusal to react, makes them a great choice for chemical processing equipment and other places where things tend to eat away at materials. It just lasts and lasts, cutting down on how often you have to fix or replace things.

Key Applications of Pure Tungsten Sheets Across Industries

1. Utilizing tungsten sheets in high-temperature furnace components and vacuum insulation

When it comes to high-temperature furnaces, especially those operating in a vacuum or with inert gases, pure tungsten sheets are practically everywhere. Their ridiculously high melting point and strength make them absolutely ideal for heating elements, heat shields, and all sorts of structural bits inside. These applications demand materials that can handle extreme temperature swings and keep that vacuum sealed tight. And honestly, I’ve found that hot zone thermal shields made from tungsten are particularly effective – they just work.

2. Integrating pure tungsten into electronics for heat sinks and sputtering targets

In the electronics world, pure tungsten sheets play a really vital role, acting as both heat sinks and sputtering targets. Their excellent thermal conductivity means they’re brilliant at pulling heat away from delicate electronic components, stopping them from getting sluggish or failing. And as Tungsten Sputtering Target, they’re absolutely essential for laying down those super-thin films in semiconductor manufacturing and other microelectronics. It’s all about making sure our modern gadgets are precise and reliable.

3. Employing tungsten sheets in medical imaging for X-ray targets and radiation shielding

Tungsten’s high density and atomic number make it a fantastic material for medical imaging. You’ll often find it in X-ray targets, where its high melting point means it can absorb those intense electron beams without breaking down. Plus, tungsten sheets are excellent at providing Tungsten Alloy Radiation Shielding against X-rays and gamma rays, keeping both patients and medical staff safe. This is all about ensuring safety and getting accurate diagnoses in healthcare.

4. Applying tungsten in aerospace and defense for critical structural components

The aerospace and defense folks really lean on pure tungsten sheets because of their amazing strength-to-weight ratio (yes, even with that high density!) and how well they perform in extreme heat. You’ll find them in crucial structural components, missile parts, and high-performance engine bits. These are the kinds of applications that demand materials tough enough to handle insane operational conditions, like screaming speeds and intense thermal loads. It’s clear to me that tungsten plays a vital role in making these advanced systems more durable and reliable.

5. Exploring other specialized uses for pure tungsten sheets in various sectors

Beyond the big applications, pure tungsten sheets pop up in all sorts of specialized areas. Think about making high-performance electrodes for welding or electrical discharge machining (EDM). They’re also used in scientific labs for equipment and in creating specialized tools. Honestly, their unique properties just keep pushing innovation across so many different industrial sectors.

If you’re interested, check 《Tungsten Copper Composite Material An Efficient Electrode Material For Multiple Applications》.

Manufacturing and Quality Control of Pure Tungsten Sheets

1. Overview of the powder metallurgy process for producing tungsten sheets

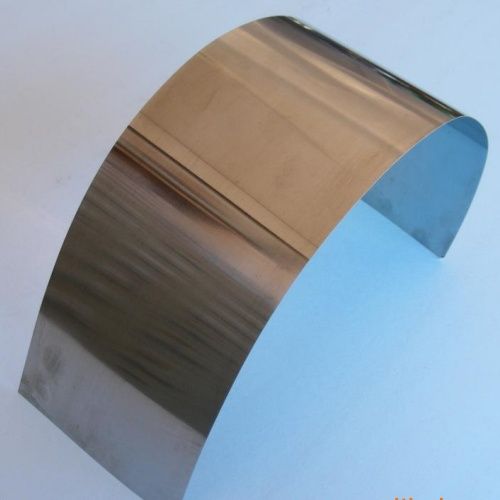

Making pure tungsten sheets mostly comes down to something called powder metallurgy. It all starts with tungsten powder, which gets pressed, then sintered (that’s basically baking it at really high temperatures), and finally rolled or forged. Sintering compacts that powder into a solid, dense form. Then, the mechanical working after that refines the grain structure and makes the material even stronger, giving you those high-quality Tungsten Plate Tungsten Sheet.

2. Ensuring purity and consistency in tungsten sheet production

Keeping tungsten sheets super pure and consistent is absolutely critical. We’ve got really strict quality control checks at every single step of the manufacturing process. That means being super careful about picking the raw tungsten powder, precisely controlling those sintering temperatures, and keeping a close eye on things during rolling. All these steps are designed to minimize any impurities and make sure the material is uniform throughout the sheet.

3. Understanding different grades and specifications of pure tungsten sheets

You know, pure tungsten sheets aren’t just a one-size-fits-all kind of thing. They come in different grades and specifications, each one tweaked for specific uses. These grades often vary in how pure they are, the size of their grains, and their mechanical properties. For example, some jobs demand ultra-high purity tungsten, while others might care more about specific strength or how flexible it is. We actually work pretty closely with our clients to figure out exactly which grade is going to be perfect for their project.

4. The importance of advanced testing methods for quality assurance

Using advanced testing methods isn’t just a nice-to-have; it’s absolutely essential for making sure pure tungsten sheets are top-notch and perform as expected. These tests include chemical analysis to confirm purity, mechanical tests to check strength and hardness, and non-destructive tests to sniff out any hidden flaws. We even use ultrasonic inspection and eddy current testing to catch any unseen issues. This thorough testing is our guarantee that our products hit the highest industry standards.

5. Customization options for dimensions, thickness, and surface finish

We’re pretty flexible here – we offer a ton of customization options for pure tungsten sheets to really nail what each client needs. That means you can get different dimensions, thicknesses, and even surface finishes. Clients can ask for precise cuts, polished surfaces, or very specific tolerances for their applications. This flexibility ensures that our tungsten sheets fit perfectly into whatever system they’re destined for.

Choosing the Right Supplier for Your Pure Tungsten Sheet Needs

1. Identifying reliable manufacturers with extensive experience in tungsten products

When you’re trying to find pure tungsten sheets, picking a reliable manufacturer is, well, crucial. You really want to look for companies that have a solid track record and a ton of experience making high-quality tungsten products. Those kinds of manufacturers will have the technical know-how and the facilities to meet even the toughest specifications. My advice? Prioritize suppliers who really specialize in refractory metals.

2. Evaluating a supplier’s technical expertise and production capabilities

You really need to dig in and evaluate a supplier’s technical smarts and what they can actually produce. That means looking at their R&D investments, their manufacturing processes, and if they can handle complex orders. A supplier with strong technical support can offer you some seriously valuable insights and solutions for those tricky application challenges. I truly believe that strong technical capabilities directly translate into a better quality product.

3. The benefits of partnering with an ISO-certified enterprise for quality assurance

Partnering with an ISO-certified company? That’s a huge win for quality assurance. ISO certification basically tells you that a company is sticking to internationally recognized standards for quality management. This commitment means consistent product quality, reliable processes, and a constant drive to get better. FOTMA, for example, is an ISO-9000-1:2008 certified enterprise, and that really shows our dedication to being excellent.

4. Considering global reach and efficient logistics for timely delivery

For a lot of industrial buyers, how far a supplier can reach globally and how efficiently they handle logistics are really big deals. Being able to deliver products worldwide, quickly and securely, cuts down on project delays and keeps your supply chain running smoothly. So, definitely check out a supplier’s shipping capabilities, how good they are with customs, and their overall logistics network. We actually pride ourselves on how efficient our global delivery systems are.

5. How to ensure competitive pricing without compromising on material quality

Getting a good price without sacrificing quality? That takes some careful thought. Ask for detailed quotes, compare different pricing structures, and don’t be afraid to ask about any extra services they offer. A good, reputable supplier will be upfront about their pricing and show you why their high-quality products are worth it. Our focus is always on giving you the best possible value through top-notch materials and service.

If you’re interested, check 《Tzm Alloy Price Analysis Value And Procurement Strategy》.

Partner with FOTMA for Your Tungsten Sheet Requirements

For top-tier pure tungsten sheets and other advanced material solutions, honestly, you should really consider partnering with Hubei Fotma Machinery Co., Ltd. We’ve got modern production equipment, plus over 30 years of deep technical expertise in refractory metals – it’s a pretty good combination, if I do say so myself. And our ISO-9000-1:2008 certification? That just underlines our unwavering commitment to excellence and reliability. Seriously, reach out to us today; let’s chat about what you need and see how our materials can really boost your projects.

Email: bunny@fotma.com, export@fotma.com

Phone: +86 13995656368, +86 13907199894

About the Author

Alex Chen is an After-Sales Engineer at Hubei Fotma Machinery Co., Ltd. He is dedicated to ensuring clients receive timely solutions and achieve optimal performance from their products. Passionate about problem-solving and continuous improvement, Alex provides expert insights and practical guidance to help customers maximize the value of their purchases.

FAQs

1. What are the primary advantages of using pure tungsten sheets over other refractory metals?

Well, pure tungsten sheets really bring a lot to the table. They boast the highest melting point of any metal, incredible strength even when things are super hot, and a superior density. These qualities make them absolutely perfect for those extreme environments where other tough metals just wouldn’t cut it. Plus, their excellent electrical and thermal conductivity are huge bonuses in specialized applications.

2. How does the manufacturing process ensure the high purity of tungsten sheets?

The manufacturing process for pure tungsten sheets typically relies on powder metallurgy. It starts with incredibly pure tungsten powder, which then gets pressed and baked at really high temperatures (sintered). After that, rolling and forging steps further refine the material. We also have strict quality checks at every stage, including analyzing for impurities and examining the microstructure, just to make sure the final product stays super pure.

3. Can pure tungsten sheets be customized for specific dimensions or applications?

Absolutely, pure tungsten sheets are incredibly versatile and can be customized a lot. Manufacturers can tweak the dimensions, thickness, and even the surface finish to perfectly match what a specific application needs. This customization ensures an ideal fit and top performance in complex systems, whether you’re talking about tiny electronic components or massive industrial furnace parts. My advice? Always talk to your supplier about your specific customization needs.

4. What industries most commonly utilize pure tungsten sheets?

You’ll find pure tungsten sheets mostly in industries that absolutely demand materials that can handle extreme temperatures, boast high density, and conduct electricity and heat really well. That includes aerospace for structural components, electronics for things like heat sinks and sputtering targets, medical imaging for X-ray targets and radiation shielding, and even in high-temperature furnace manufacturing for heating elements and insulation.

5. How can I determine the right grade of pure tungsten sheet for my project?

Figuring out the right grade really comes down to looking at your project’s specific needs – things like the operating temperature, how much mechanical stress it’ll face, what you need for electrical conductivity, and the required purity levels. Honestly, talking to experienced material engineers or suppliers is highly recommended. They can help you match the perfect tungsten grade to your application, ensuring you get the best performance and value.

Keywords

pure tungsten sheet, tungsten sheets, tungsten properties, high melting point tungsten, tungsten density, tungsten strength, thermal conductivity tungsten, electrical conductivity tungsten, corrosion resistance tungsten, high-temperature furnace components, vacuum insulation, electronics heat sinks, sputtering targets, X-ray targets, radiation shielding, aerospace components, defense applications, powder metallurgy tungsten, tungsten sheet manufacturing, quality control tungsten, tungsten grades, customized tungsten sheets, tungsten suppliers, ISO-certified tungsten, industrial materials

We Exist to Make Your Projects Successful

Fill out the form below and someone from our team will be in touch with you!

FOTMA Delivers Professional Ultra-Dense Solutions, Lighter on Cost, Heavier on Performance.

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074