ABOUT

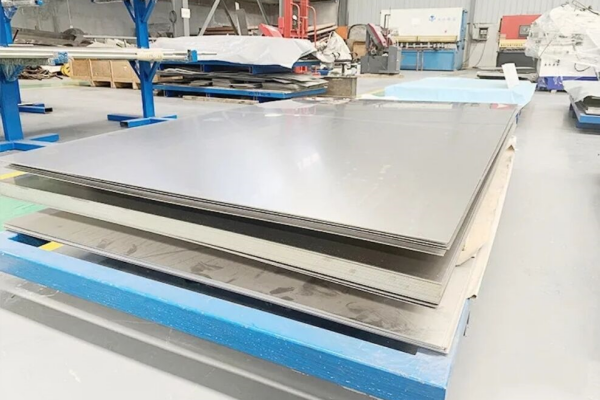

Unveiling the Versatility of Thin Titanium Sheets

Thin titanium sheets sit right at the intersection of weight targets, corrosion challenges, and reliability, which is exactly where most of my customer calls land. As an after-sales engineer, I am often asked to weigh strength against mass, or durability against harsh media, and thin titanium has a way of ticking those boxes with less compromise than most materials. What follows is the same set of practical checks and field-proven insights I use when helping engineers and buyers make confident, high-performance choices.

Understanding the Unique Attributes of Thin Titanium Sheets

1. What makes titanium an exceptional material choice

Titanium earns its place on the shortlist because of its standout strength-to-weight ratio. It comes in significantly lighter than steel while delivering comparable or better strength, which matters when every gram counts. It also resists corrosion impressively, especially against chlorine, saltwater, and many industrial chemicals, so components last longer in punishing environments. Add its biocompatibility, the body accepts it without adverse reactions, and it becomes a natural fit for medical use. Put together, these traits make titanium a go-to for specialized engineering problems where performance margins are narrow.

2. Exploring the key properties of thin titanium sheets

Thin titanium sheets hold the same core advantages of titanium but open up design flexibility. Reduced thickness magnifies the strength-to-weight benefit, so structures get lighter without surrendering integrity. Corrosion resistance remains intact, delivering durable service in tough conditions. They form well, which helps when complex shapes or tight radii are on the drawing board. They also keep their strength at elevated temperatures, which is why aerospace and high-performance automotive teams value them. The net result is a material format that enables more ambitious designs with fewer trade-offs.

3. How manufacturing processes influence sheet quality and performance

Manufacturing routes shape the final performance. Rolling, annealing, and surface treatments determine microstructure and mechanical behavior. Cold rolling raises strength and improves surface finish, while hot rolling handles larger reductions. The anneal needs tight temperature and time control to hit the right balance of ductility and strength. Surface treatments, such as pickling or passivation, help boost corrosion resistance and set the surface for secondary processes or coatings. We keep strict quality gates through each step, which protects the consistency you need at production scale.

Diverse Applications Driving Demand for Thin Titanium Sheets

1. Revolutionizing aerospace and defense with lightweight solutions

Aerospace and defense lean heavily on thin titanium sheets for their strength-to-weight advantage and corrosion resistance. Aircraft skins, engine components, and structural frames benefit from weight reduction, which translates into better fuel efficiency and more payload. The material’s fatigue performance and high-temperature capability support long service life in critical uses. We provide aerospace-grade titanium sheets that meet the rigorous specifications of this industry.

You might be interested in reading more about titanium’s role in advanced engineering, check Chinas Titanium Industry Breaks Through To High End Development.

2. Advancing medical implants and surgical instruments

In medical settings, thin titanium sheets earn trust for their biocompatibility and resistance to corrosion inside the body. They appear in surgical instruments, bone plates, dental implants, and pacemakers. The non-toxic nature and ability to integrate with bone help reduce rejection and support healing. Precision fabrication of thin sheets delivers the intricate geometries these devices demand.

3. Enhancing chemical processing equipment and corrosion resistance

Chemical processing is hard on metals, which is where thin titanium sheets shine. They withstand aggressive media, including acids, alkalis, and chlorides, so they are used to line tanks, build heat exchangers, and protect piping where other alloys fail quickly. The durability cuts maintenance spend and extends equipment life. We supply high-purity titanium designed to hold up under extreme chemical exposure.

4. Innovating in automotive, marine, and consumer electronics

Use cases are expanding. In high-performance automotive parts, thin titanium sheets help drop weight while staying tough. In marine environments, their resistance to saltwater is a clear advantage. In consumer electronics, the combination of a sleek look, strength, and low mass elevates high-end devices and luxury products. The versatility of Titanium Sheet Titanium Alloy Plates continues to fuel new designs across these sectors.

For further insights into titanium applications, consider reading Titanium And Titanium Alloys Widespread Application And Future Challenges.

Key Considerations When Selecting Thin Titanium Sheets

1. Evaluating different titanium grades and their specific benefits

Picking the right grade shapes both performance and cost. Each grade brings a different mix of strength, ductility, and corrosion resistance, so the fit depends on your operating environment and design priorities.

| Titanium Grade | Key Characteristics | Primary Benefits | Typical Applications |

|---|---|---|---|

| Grade 1 (CP Ti) | Unalloyed, lowest strength | High ductility, excellent corrosion resistance | Chemical processing, medical implants, marine |

| Grade 2 (CP Ti) | Unalloyed, moderate strength | Good formability, excellent corrosion resistance | Heat exchangers, architectural components |

| Grade 5 (Ti-6Al-4V) | Alpha-beta alloy, most common | High strength, good fatigue resistance, heat treatable | Aerospace, medical implants, high-performance automotive |

| Grade 7 (Ti-0.15Pd) | CP Ti with palladium | Enhanced corrosion resistance in reducing acids | Chemical processing, highly corrosive environments |

| Grade 9 (Ti-3Al-2.5V) | Alpha-beta alloy | Moderate strength, good cold workability | Aircraft hydraulic tubing, sports equipment |

Understanding these distinctions allows for informed material selection, ensuring the chosen material meets the specific demands of the project. For instance, Grade 5 is often preferred when high strength and elevated temperature performance are critical.

To learn more about the different types of titanium alloys, refer to What Is The Most Commonly Used Titanium Alloy.

2. Ensuring quality and compliance with industry standards

Quality and standards are non-negotiable. We back our material with chemical composition checks, mechanical property testing for tensile strength, yield strength, and elongation, and non-destructive evaluations such as ultrasonic and eddy current. Compliance with ASTM, AMS, and ISO keeps performance aligned with international benchmarks. This framework gives you predictable behavior from prototype to production.

3. Customization options for specific project requirements

Projects often need more than a catalog size. We support custom thicknesses, widths, lengths, and surface finishes, along with targeted mechanical properties when the design calls for them. Our engineers work directly with your team so the sheet integrates with your tooling, geometry, and load cases. This tailoring helps curb scrap and improve throughput on specialized builds.

Partnering with an Expert Supplier for Your Titanium Needs

1. Hubei Fotma Machinery Co., Ltd.’s commitment to quality and expertise

Hubei Fotma Machinery Co., Ltd. is an ISO-9000-1:2008 certified enterprise with a long track record of technical depth. Our core team brings over 30 years of accumulation in material research, which supports consistent quality in both domestic and international projects. With modern production equipment and advanced testing methods, we validate every lot against strict requirements. That reliability is what our customers count on in demanding applications.

2. Our comprehensive range of non-ferrous metal materials

Beyond thin titanium sheets, we supply tungsten-molybdenum products, tungsten-molybdenum alloys, tungsten-copper alloys, cemented carbide, high-density alloys, and nickel. This range serves aerospace, medical, electronics, and chemical processing, among others. One source for multiple materials keeps procurement simpler and faster.

3. How Fotma supports your project from concept to delivery

We stay engaged from the first concept conversation to the final shipment. That support includes material selection input, design-for-manufacture checks, and process recommendations. Execution tracks your specifications and quality controls, and our supply chain team keeps delivery schedules on target so builds can stay on plan.

Contact Us Today

For expert advice, custom solutions, or to request a quote for your thin titanium sheet requirements, contact Hubei Fotma Machinery Co., Ltd. Our dedicated team is ready to assist you.

Email: bunny@fotma.com, export@fotma.com

Phone: +86 13995656368, +86 13907199894

FAQs

1. What are the primary advantages of using thin titanium sheets over other metals?

They deliver an excellent strength-to-weight ratio, which makes them ideal for lightweighting without compromising performance. Corrosion resistance is strong in harsh chemical and marine environments. The material’s biocompatibility also makes it suitable for medical and implantable devices where the body’s response matters.

2. How does the thickness of titanium sheets impact their applications?

The thickness of Titanium Sheet Titanium Alloy Plates directly influences their flexibility, weight, and strength. Thinner sheets are more pliable and lighter, which suits intricate shapes or strict weight targets such as aerospace skins or consumer electronics. Thicker sheets provide higher structural integrity for components that must carry more load.

3. Can thin titanium sheets be easily welded or formed?

Yes, with the right approach. Titanium’s reactivity means welding requires inert gas shielding to prevent contamination. Forming calls for appropriate tooling and controlled processes to achieve the geometry without degrading properties.

4. What are the typical lead times for custom thin titanium sheet orders?

Lead time depends on complexity, quantity, and processing steps, with standard custom orders often running 4 to 8 weeks. Share your specifications with our sales team for a precise timeline.

5. How does Hubei Fotma ensure the quality of its titanium products?

We operate under ISO-9000-1:2008 certification and maintain full traceability, in-process inspections, and final testing. Verification covers chemical composition, mechanical properties, and dimensional accuracy, so delivered material aligns with your drawings and standards.

We Exist to Make Your Projects Successful

Fill out the form below and someone from our team will be in touch with you!

FOTMA Delivers Professional Ultra-Dense Solutions, Lighter on Cost, Heavier on Performance.

Hubei Fotma Machinery Co. Ltd.

Wechat / Whatsapp / Mobile:

+86 13995656368, +86 13907199894

Tel: +86-27-67845266

Email: bunny@fotma.com, export@fotma.com

Address: Guanggu Avenue 52#, Hongshan, Wuhan,

Hubei province, P.R.China. 430074